GT 650

Fra 2004 og frem.

Servicemanual

Holtvej 8-10, Høruphav

6470 Sydals

Telefon: +45 73 15 11 00

Fax: +45 73 15 11 01

E-mail: [email protected]

www.scanmi.dk

CVR: 27 73 31 07

Summary of Contents for GT 650

Page 5: ...NOTE Difference between photographs and actual motorcycles depends on the markets ...

Page 13: ...1 7 GENERAL INFORMATION EXTERIOR ILLUSTRATION ...

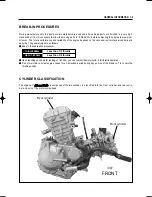

Page 102: ...CARBURETOR 4 3 FUEL SYSTEM ...

Page 138: ...LAMP HEADLAMP TURN SIGNAL LAMP TAIL BRAKE LAMP ELECTRICAL SYSTEM 6 16 ...

Page 158: ...7 15 CHASSIS FRONT FORK ...