15

CHANGES AND T YPING ERRORS RESERVED

CHANGES AND T YPING ERRORS RESERVED

7. o

peraTion

insTrucTions

7.1. s

TarTing

The

machine

•

Before starting the machine, read carefully the operation manual and become fully acquainted with all the

details.

•

The operator should be familiar with all the rules and points of attention for running and maintaining the

machine.

•

Strictly follow the instructions for lubrication. Fill the oiling places with lubricant at regular intervals.

•

When you push in the tool unloading spacing shaft, there should be a clearance between the end of the

taper shank of the spiral drill and the ram of the tool unloading device. Unqualified taper shanks and sleeve

adapters can not be used.

•

Remove all the anti-rust coating or grease from the machine. Fil the machine with lubricant. Run the machine

from low to high speed without load and check for normal functioning.

7.2. d

escripTion

of

conTrol

elemenTs

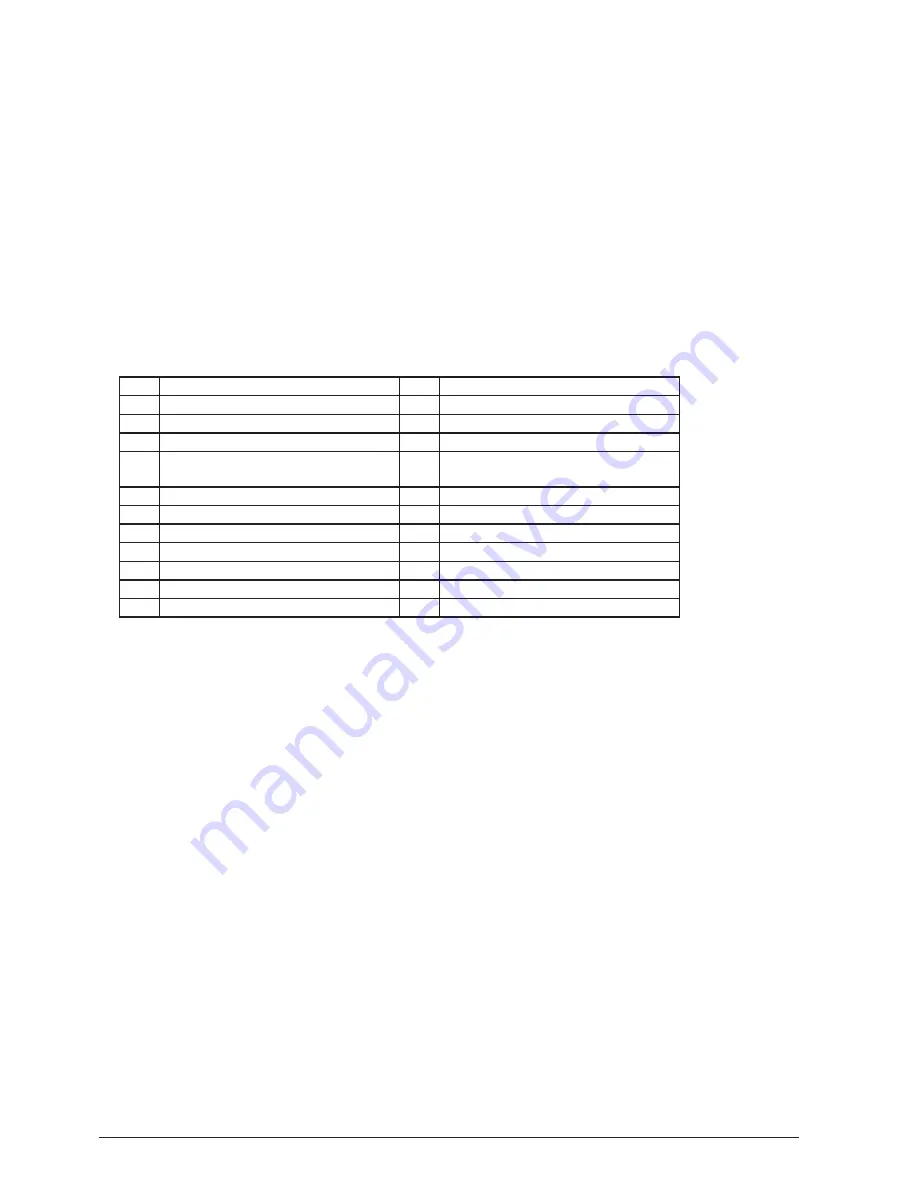

See figure A

7.2.1. p

osiTion

of

The

conTrol

elemenTs

1

Table bracket lift handle

13

Electrical cabinet handle

2

Feed depth adjusting handle

14

Table bracket lowering button

3

Feed depth leadscrew lock handle

15

Main motor start button

4

Hand feed handle

16

Main motor stop button

5

Connect/disconnect button for

electromagnetic feed clutch

17

Lamp button

6

Feed regulating lever

18

Coolant pump button

7

Coolant supply valve

19

Tapping select button

8

Spindle speed change handle A

20

Motor speed switch

9

Spindle speed change handle B

21

Power supply switch

10

Table bracket lifting button

22

Table clamp/loose lever

11

Emergency stop button

23

Bracket clamp/loose lever

12

Tool unload handle

7.3. s

pindle

speed

change

conTrol

The 12 steps of the spindle speed are accomplished by a gear driving system and 2-speed motor (see figure E).

To change the speed, first stop the motor.

Turn the speed change handles (8 and 9) to the desired position. Then turn the switch (20) to position 1 or 2. The

speed for forward is selected. Turn the switch to position “R” for the same speed in reverse running.

7.4. s

pindle

feed

operaTion

7.4.1. a

uTomaTic

feed

First stop the motor. Turn the feed change lever (6) tot the desired feed rate on the feed chart. Push down the

button (5) on the end of the hand feed lever (4) to engage the electromagnetic clutch. Auto feed with the

selected speed starts. If you need to stop during the process, push button (5) on the control panel to disengage

the electromagnetic clutch.

7.4.2. h

and

feed

Turn the handles (4) counter clockwise for hand feed of the spindle during drilling.

7.4.3. T

apping

The auto feed button should not be pushed down when tapping, because the spindle feeds according to the

pitch. For safety, please turn the tapping select button (19) to the tapping position and keep it interlocked with

auto feed.

Summary of Contents for HU 40 TI

Page 1: ...HU 40 TI HU 40 TI D R I L L I N G M M A C H I N E S...

Page 2: ...2 A B C A1 A2 A3 A4 A5 A6 A7 CHANGES AND TYPING ERRORS RESERVED...

Page 3: ...3 D E CHANGES AND TYPING ERRORS RESERVED...

Page 4: ...4 F G H CHANGES AND TYPING ERRORS RESERVED...

Page 5: ...5 I J3 J2 J1 J4 CHANGES AND TYPING ERRORS RESERVED...

Page 6: ...6 K L CHANGES AND TYPING ERRORS RESERVED...

Page 7: ...7 M CHANGES AND TYPING ERRORS RESERVED...

Page 8: ...8 N CHANGES AND TYPING ERRORS RESERVED...

Page 9: ...9 O CHANGES AND TYPING ERRORS RESERVED...

Page 23: ...23 CHANGES AND TYPING ERRORS RESERVED...

Page 26: ...26 CHANGES AND TYPING ERRORS RESERVED...

Page 27: ...27 CHANGES AND TYPING ERRORS RESERVED...

Page 28: ...2014 V1...