D.13

TE 250 - 310 2012 I.E. / TE 250 - 310 2012 I.E. USA

TC 250 2012 - TC 250 2012 I.E. USA

TXC 250 - 310 2012 I.E. USA

H09067

2

1

1

3

C

A

4mm (0,16 in.)

D

H10957

Workshop Manual Ed. 12-2011

SETTINGS AND ADJUSTMENTS

- Remove the plates (8), lubricate the new plates with engine oil and install

them (always start with a friction plate).

Refit clutch actuator plate, bearing and pressure plate.

Tighten the spring screws gradually in a cross pattern (8 Nm - 0.8 Kgm - 5.8 ft/

lb).

When refitting the clutch cover (8 Nm - 0.8 Kgm - 5.8 ft/lb), check gasket for

wear and replace as required.

For additional information on assembly procedures, see Section

"H" Engine assembly.

Hydraulic clutch lever adjustment and fluid level check

Free play (A) must be at least 0,39 in. (10 mm).

The lever position can be adjusted to suit the rider hand size.

To decrease the lever distance from the handgrip, rotate the adjuster (B)

CLOCKWISE.

To increase the lever distance from the handgrip, rotate the adjuster (B) COUN

-

TER CLOCKWISE.

Fluid level is checked as follows:

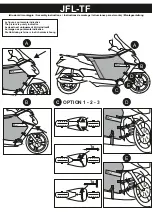

- Remove screws (1), cover (2) and rubber diaphragm from the control;

- Keep the control cylinder (3) in a horizontal position and make sure that fluid

level has not dropped lower than 4 mm (0.16 in.) below the upper edge (D)

of master cylinder body;

- If needed, top up with the fluid specified in the LUBRICANT CHART included

in Section "A".

Refit any parts you have removed.

Periodically check the connecting hose (see “Scheduled Maintenance Chart”);

if hose (C) is worn or cracked, its replacement is advised.