Floor type

Blade application

Wood and wood like floors

Pre-saw the wood with a circular saw. Pound down or remove any nails or metal

obstruction to avoid blade damage.

Glued hard wood flooring

For correct removal of hardwood flooring (plank solid, plank laminated, parkay,

parquetry laminated), the flooring must be pre-sawed. This is done by using a

circular saw set at a depth of 99% of the thickness of the board, just missing the

subfloor surface. Draw chalk lines across the floor and pre-saw to blade width.

(every 152mm).

True parkay flooring scoring is not necessary. It will come up in small pieces. When

working over plywood sub-flooring, try to run machine in the same direction as the

grain in the wood. Blade in most cases bevel down. On solid wood floors like plank,

run in the same direction as the plank, not cross grain or cross plank. Removing the

front counterweights will help on all soft surfaces.

Concrete

When working on concrete slab, normal blade position is bevel up for best perform-

ance, especially when cleaning adhesive. On occasion, bevel down gives better

blade life.

Maintenance

Introduction

WARNING:

Before you do

maintenance, you must read and

understand the safety chapter.

For all servicing and repair work on the product, special

training is necessary. We guarantee the availability of

professional repairs and servicing. If your dealer is not

a service agent, speak to them for information about the

nearest service agent.

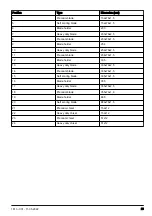

Maintenance schedule

* = General maintenance done by the operator. The

instructions are not given in this operator's manual.

X = The instructions are given in this operator's manual.

O = The instructions are not given in this operator's

manual. Let an approved service agent do the

maintenance.

Maintenance

Daily

Week-

ly

Each

12

month

s

12 h

after

servic-

ing

Clean the product.

X

Do a check of all safety devices.

*

Do a check of the RCD.

*

Do a check of the wear and sharpness of the blade.

X

Make sure that all electrical connectors are clean.

X

Make sure that the motors are clean.

*

Clean the external surfaces of the product.

X

Clean the internal components of the product.

O

Do a general inspection.

X

Make sure that all screws and nuts are tightened with the correct torque.

X

X

1813 - 001 - 11.05.2022

13

Summary of Contents for BMS 220 ADB

Page 97: ...1813 001 11 05 2022 97 ...

Page 98: ...98 1813 001 11 05 2022 ...

Page 99: ...1813 001 11 05 2022 99 ...