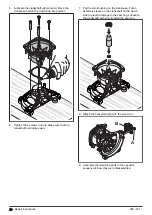

6. Disassemble the bearing (X) on the output shaft

(AA). If it is necessary, hit the gear housing (L)

against a wooden block until the bearing falls out.

Disassemble the gear wheel (Y) and bearing (Z)

from the output shaft (AA).

Y

Z

AA

X

L

7.14.4 To assemble the bevel gear

1. Put the gear wheel (Y) on the output shaft (AA).

Y

Z

AA

X

L

2. Install the 2 bearings (Z and X).

3. Increase the temperature of the gear housing to

approximately 140°C with a hot air gun.

4. Put the output shaft into the gear housing (L). Make

sure that the bearings are in their correct positions. If

it is necessary, use a bearing press of an applicable

size.

5. Make sure the output shaft is attached to the gear

housing.

6. Install the bearings (T and U) on the input shaft (V).

Install the snap ring (S) to the input shaft (V). Make

sure that the gear housing is approximately 110°C.

U

V

Q

T

S

R

7. Put the input shaft assembly (Q) into the housing

with a pair of pliers.

935 - 001 -

Repair instructions- 55

Summary of Contents for 531RB

Page 1: ...Workshop manual 541RB 531RB English 935 001 ...

Page 10: ...5 Servicing tools 10 8 3 11 12 9 1 2 4 5 6 7 13 14 15 16 10 Servicing tools 935 001 ...

Page 61: ...935 001 Technical data 61 ...

Page 62: ...62 Technical data 935 001 ...

Page 63: ...935 001 Technical data 63 ...

Page 64: ...114 10 74 26 2019 04 18 ...