8

JIN04MKIIC_V1 10/01/17

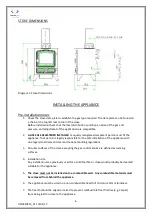

FLUE ARRANGEMENT

Prior to installation the flue the chimney should be given a precautionary clean to ensure its entire length is

free from blockages. Any flue dampers must be permanently fixed in the open position or removed

altogether. The chimney should be smoke tested to ensure soundness.

The GAS SAFE REGISTERED ENGINEER commissioned to install this appliance is wholly responsible for

deciding the suitability of any flue arrangement to operate in conjunction with this gas appliance.

The chimney or flue system that is to be fitted to the Hawk 4 MKII gas stove must comply with the current

rules in force.

The Hawk 4 MKII gas stove is also suitable for other specific class II installation arrangements: pre-cast flues,

ridge-vent flues, and pre-cast chimney block.

It is suggested to run flue pipe at least 615mm vertically from the unit before there are any changes in

direction of the flue system. Wherever possible horizontal runs of the flue system should be avoided.

The flue must have a minimum of 2.6 meters of vertical height measured from the top of the stove to the

bottom of the terminal outlet.

Please note for rear flue appliances it is recommended that the vertical flue run be established as soon as is

practical from the rear flue exit. (Caution should be taken locating the exit of the flue as explained in ‘The

Building Regulations - Document J’.)

ADDITIONAL AIR VENTING (GB ONLY)

The supply gas heat input into the appliance is nominally less that 7kW. Therefore, under the directives of

the current Health and Safety Executive gas safety and use regulations (Gas Safety [Installation and Use]

Regulations 1998 Approved Code of Practice and guidance) no additional air vents are required in the room

in which the appliance is situated.