NOTE:

If you have a flat-bottomed aluminum boat, some additional adjustment

may be needed to accommodate the rivets on the bottom of the boat (i.e. the gap

may need to be a little smaller than 1/8"). This will help you to avoid excessive

turbulence at high speeds.

NOTE:

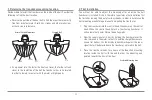

If your propeller moves clockwise (in forward, as you're facing the stern of

the boat from behind), mount the transducer on the starboard side, and align the

bottom right corner of the mounting bracket with the bottom of the boat. If your

propeller moves counter-clockwise (in forward, as you're facing the stern of the

boat from behind), mount the transducer on the port side, and align the bottom

left corner of the mounting bracket with the bottom of the boat.

3. Continue to hold the bracket on the transom

of the boat, and use a pencil or marker to

mark where to drill the two mounting holes.

Mark the drill holes near the top of each

slot, making sure that your mark is centered

in the slot.

4. Make sure that the drill bit is perpendicular

to the actual surface of the transom, NOT

parallel to the ground, before you drill.

Using a 5/32” bit, drill the two holes only to

a depth of approximately 1”.

NOTE:

On fiberglass hulls, it is best to use progressively larger drill bits to reduce

the chance of chipping or flaking the outer coating.

3. Assembling the Transducer and Initial Mounting

In this procedure, you will assemble the transducer using the hardware

provided, then mount it and make adjustments to its position without locking

it in place.

NOTE:

You will initially assemble the transducer and the pivot arm by matching

the two ratchets to a numbered position on the transducer knuckle. Further

adjustments may be necessary.

1a. If you already know your transom angle, refer to the chart below for

the initial position to use to set the ratchets. If your transom is

angled at 14 degrees (a common transom angle for many boats) use

position 1 for the ratchets. In either case, go to step 2.

or...

1b. If you do not know your transom angle, measure it using a plumb line

(weighted nylon string or monofilament line) exactly 12 inches long.

Hold the top of the plumb line against the top of the transom with your

finger, and wait until the line hangs straight down. Using a ruler,

measure the distance from the

bottom

of the plumb line to the back of

the transom, then use the chart.

NOTE:

It is important to take your measurement in the figure showing

Measuring

the Transom Angle

, from exactly 12 inches down from the top of the transom.

NOTE:

The third hole should not be drilled until

the angle and height of the transducer is finalized,

which you will not do until a later procedure.

-2 -1 0

1

2

3

4

5

6

7

8

9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

Transom Angle (°)

Bead Alignment

Number

1

4

2

5

3

1

4

2

5

25 26 27

3

28 29 30

1

Measured Distance (x)

1.1cm

1/2“

0.0 cm

0“

2.5 cm

1“

4.3 cm

1 5/8“

5.9 cm

2 3/8“

7.6 cm

3“

9.3cm

3 5/8“

11.1cm

4 3/8“

12.9cm

5“

14.9cm

5 7/8“

16.9cm

6 5/8“

Using the Mounting Bracket

to Mark the Initial Drill Holes

Mark Initial

Drill Holes

Third Hole

Fourth Hole

15