2

2

Regulation and Precautions for Board Handing

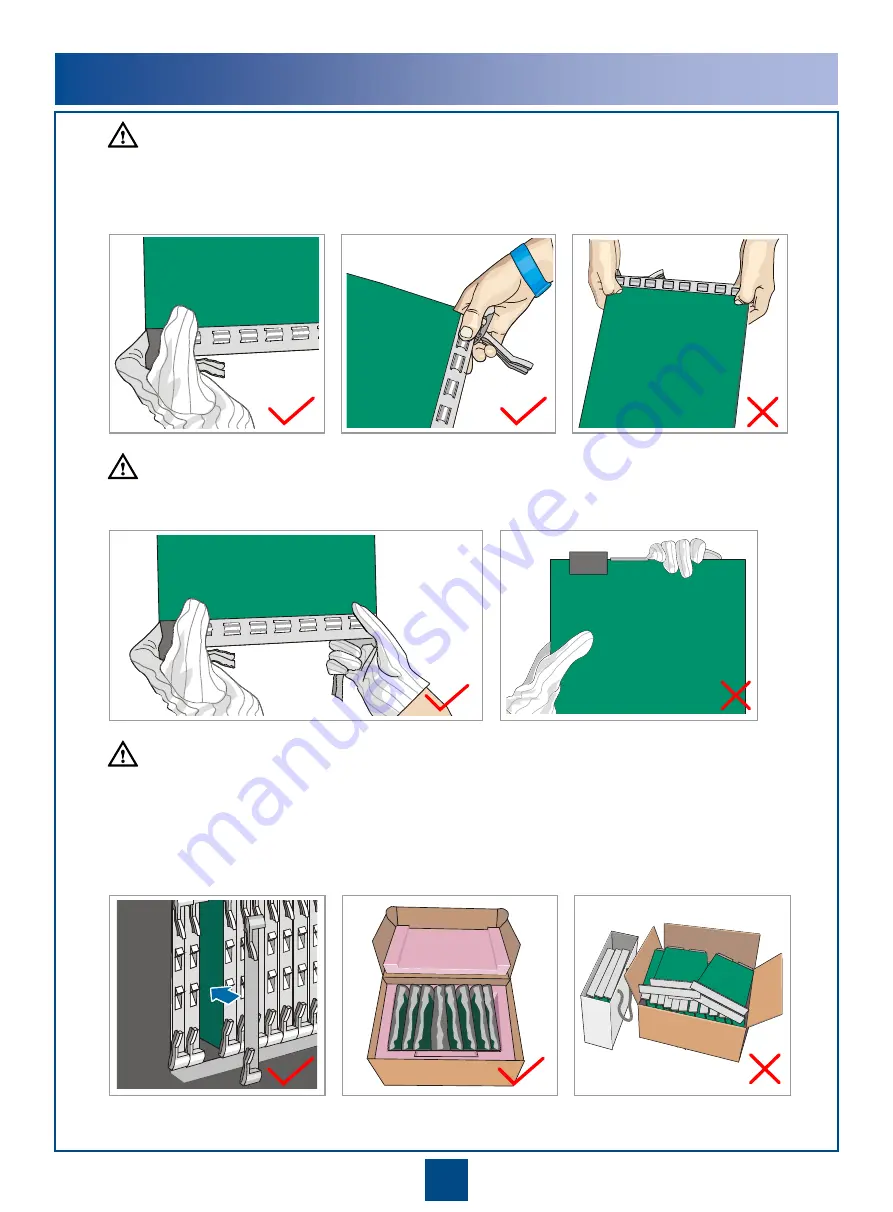

Do not hold a board without hand protection. Wear an ESD wrist strip or ESD gloves before handling a board.

Insert filler panels into vacant slots on an NE to prevent foreign matters from getting into the NE and system

air ducts from being damaged, which may resulting in faults on the NE.

Boards are fragile and valuable. When handling or placing a board, exercise caution and put it into a

dedicated packing box.

Coherent boards must be packed with original packaging materials during transportation. If the original

packaging materials are lost, contact Huawei.

Holding aboard without hand protection

Wearing ESD gloves

Wearing an ESD strip

Hold the front panel of a board with both hands.

CAUTION

CAUTION

CAUTION