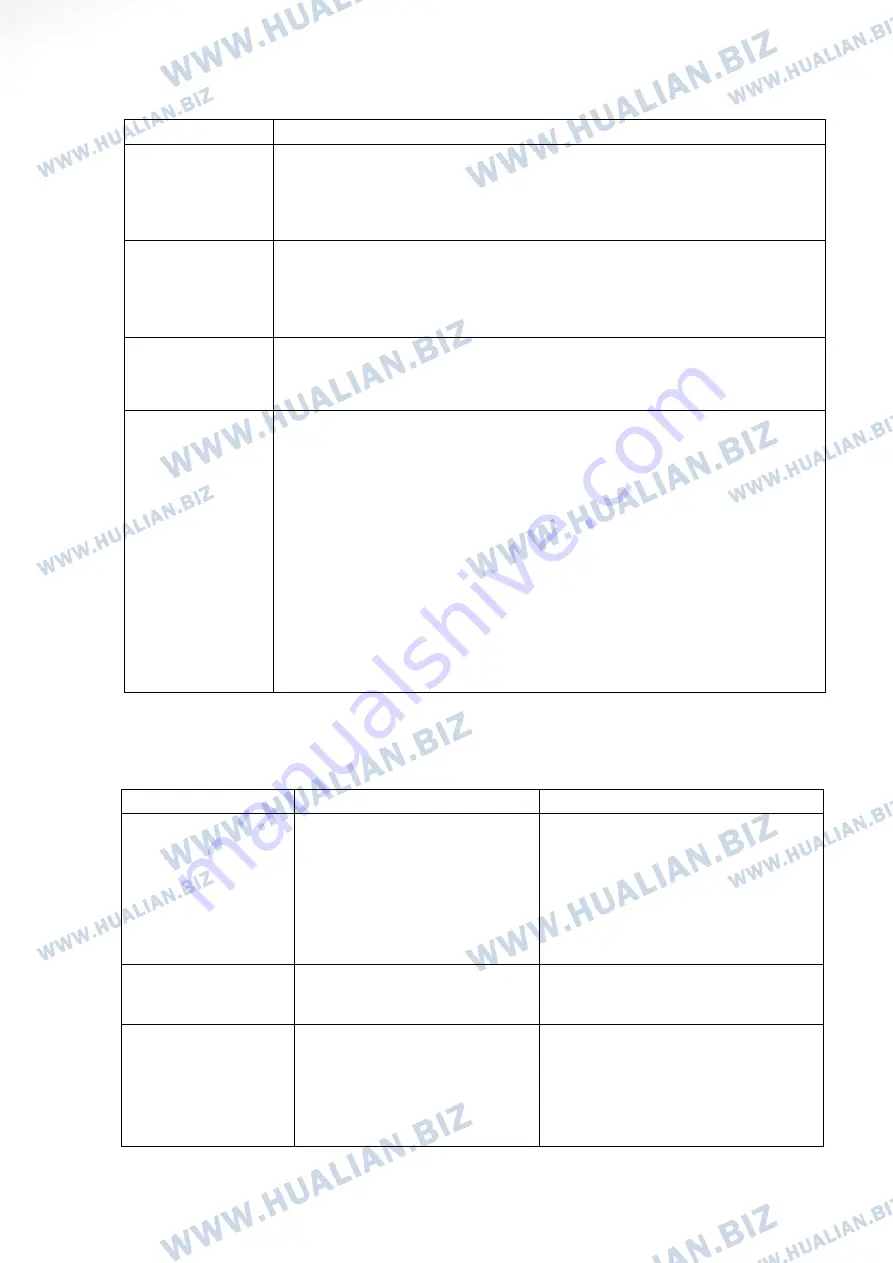

6.2 Maintenance schedule

Schedule

Contents of Maintenance

Daily

1.Use the brush to remove the substance attached to the appearance of the sealing

belt and guiding belt.

2.Use wet cloth to clean the appearance of the conveyor belt.

3. There is no noise or abnormal noise during motor operation.

Monthly

1.Check whether the sealing belt is worn or not

2.Check whether the guiding belt is worn or not

3.Clean the carbon brush of the motor

4, the inflator filter sponge cleaning

Half a year

1.Check the worn situation of the carbon brush of the motor which is suggested to

change once a year

2.Adding lubricating grease to the gears which are exposed without cover.

Year

1.General inspection shall be conducted according to the above items.

2.Check whether the rubber wheel is aging, and replace the rubber wheel if the

aging is serious.

3,Check the temperature controller temperature rise time, temperature rise to the

set value more than 10 minutes to consider replacement.

4.Check whether the switch, emergency stop, potentiometer, fan and other

electrical components operate normally.

5.Check the gear, shaft, universal joint and coupling of the transmission part, add

grease, and replace the parts with serious strain when necessary.

6.Clean the worm gear box and replace the lubricating oil (Great Wall brand 000#

extreme pressure lithium grease lubricating oil).

7 Troubleshooting

7.1 Troubleshooting

Problem

Reason

Solution

The machine does not

work

1

、

The power is not connected.

2

、

The fuse is broken or high

resolution circuit breaker trips.

3

、

The emergency stop switch is

pressed but there is no reset.

1. Check the electric outlet

2. Replace the fuse and high resolution

circuit breaker

3

、

Reset the emergency stop switch.

Conveyor belt is

off-tracking

1

、

The active axle is not parallel to

the driven axle.

1

、

Adjust two adjusting screws of Driven

Wheel Seat.

Sealing belt is easily

broken

1.Too much tension on sealing belt.

2. Sealing belt is off tracking.

3. Crease on sealing belt.

4. Adhesive film or other dirt

attached to sealing belt surface.

1. Adjust the vertical adjusting screw on

driven wheel seat, so as to make sealing

bel neither too tight nor too loose

2.

(

see the point above

)

.

3. No crease on sealing belt.

27