30

Daily:

• Clean the machine if it has been used for wet grinding

or mist spray.

• Check wear on the tools – abnormal or uneven wear

can indicate damage to the grinding holder.

• To avoid failure, check the tool holder and grinding

holder for damage or cracks. If any damage has occurred,

change the parts.

Weekly:

• Clean the machine.

• Check the grinding holders. Remove the tools and run

the machine off the ground on the lowest speed. If the

grinding holders oscillate or wobble considerably they are

damaged. Overhaul all grinding holders at the same time.

• Check that the upper belt is intact. Try to turn the large

disk in any direction. It should be stiff. If it turns freely then

the belt has broken.

Each month (or 100 hours):

• Screw into place everything that can have vibrated

loose.

• Lift off the cover and check that it is intact.

• Scrape and vacuum the parts that are enclosed by the

cover. Check the upper belt. Change as needed.

• Check the seals of the shafts the upper belt runs on.

Change as needed.

• Test run and listen for any sounds from the bearings.

Summary of Contents for 950 RX

Page 1: ...v 3...

Page 2: ......

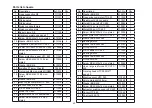

Page 34: ...32 798 1347 1287 2047 2154 1338 1196 985 Technical data...

Page 47: ...45 29 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 30 31...

Page 49: ...47 2 3 4 5 6 7 8 9 10 12 13 14 15 16 17 19 20 21 22 23 1 18 11...

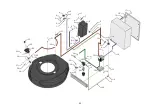

Page 53: ...51 1 2 3 1 4 5 6 7 8 9 10 11 12 13 14 15 3 2 3 2 16...