Chapter 3

3-9

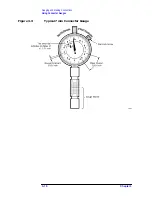

Gauging and Making Connections

General Cleaning Procedures

General Cleaning Procedures

Using Compressed Air or Nitrogen

WARNING

Wear protective eye covering at all times when using

compressed air or nitrogen.

Use compressed air or nitrogen to loosen particles on the connector

mating plane surfaces. Clean air cannot damage a connector or leave

particles or residues behind.

You can use any source of clean, dry, low-pressure compressed air or

nitrogen that has an effective oil-vapor filter and liquid condensation

trap placed just before the outlet hose. Ground the hose nozzle to

prevent electrostatic discharge, and set the air pressure to 414 kPa

(60 psi) or less. High velocity air can cause electrostatic effects when

directed into a connector.

Cleaning the Connector Threads

CAUTION

This procedure assumes you have taken the necessary ESD

precautions. Refer to

“Electrostatic Discharge (ESD)” on page 3-3

for a

description of ESD precautions.

For dirt or stubborn contaminants on a connector that you cannot

remove with compressed air or nitrogen, try a cleaning swab or lint-free

cleaning cloth moistened with isopropyl alcohol.

To clean the connector threads:

1. Apply a small amount of isopropyl alcohol to a cleaning swab or

lint-free cleaning cloth.

2. Clean the connector threads.

3. Let the alcohol evaporate, then blow the threads dry with a gentle

stream of clean, low-pressure compressed air or nitrogen.

Cleaning the Mating Plane and Interior Surfaces

Apply a small amount of isopropyl alcohol to a new cleaning swab and

clean the mating plane and interior surfaces.

If the connector has a center conductor, use very short horizontal or

vertical strokes (across the connector), and the least pressure possible,