Chapter 3

3-7

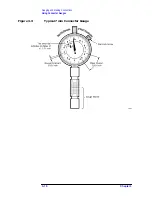

Gauging and Making Connections

Visual Inspection

Inspecting Slotless Connectors

When using slotless connectors like the 3.5 mm or type-N 50

Ω

female

connectors, pay special attention to the female center conductor contact

fingers. These are easily bent or broken, and damage to them is not

always easy to see. A connector with damaged contact fingers will not

make good electrical contact and must be replaced.

NOTE

This is particularly important when you are mating nonprecision to

precision devices.

Checking for Connector Wear

Connector wear eventually degrades performance. The more use a

connector gets, the faster it wears and degrades. This is especially true

with electrically characterized devices such as ECal modules. The wear

is greatly accelerated when connectors are not kept clean, or are

connected incorrectly. Test port connectors on the VNA test set may

have many connections each day, and are therefore subject to more

wear. It is recommended that you use an adapter as a test-port saver to

minimize the wear on the test set’s test port connectors. Replace all

worn connectors.