26

Installing a switching fabric module

Every 12910 AC switch has six switching fabric module slots numbered 10 through 15. For the proper

operation of the switch, at least one switching fabric module must be installed in slot 10, slot 11, or slot

12.

The gray edged switching fabric module slots of a 12910 AC switch are located at the rear panel. The

switching fabric modules are horizontally oriented. When installing a switching fabric module, make sure

its PCB faces up.

To install a switching fabric module:

1.

Wear an ESD-preventive wrist strap, and make sure it makes good skin contact and is well

grounded. For more information, see "

Attaching an ESD-preventive wrist strap

."

2.

Remove the filler panel (if any) from the target slot. Keep the filler panel for future use. See

.

3.

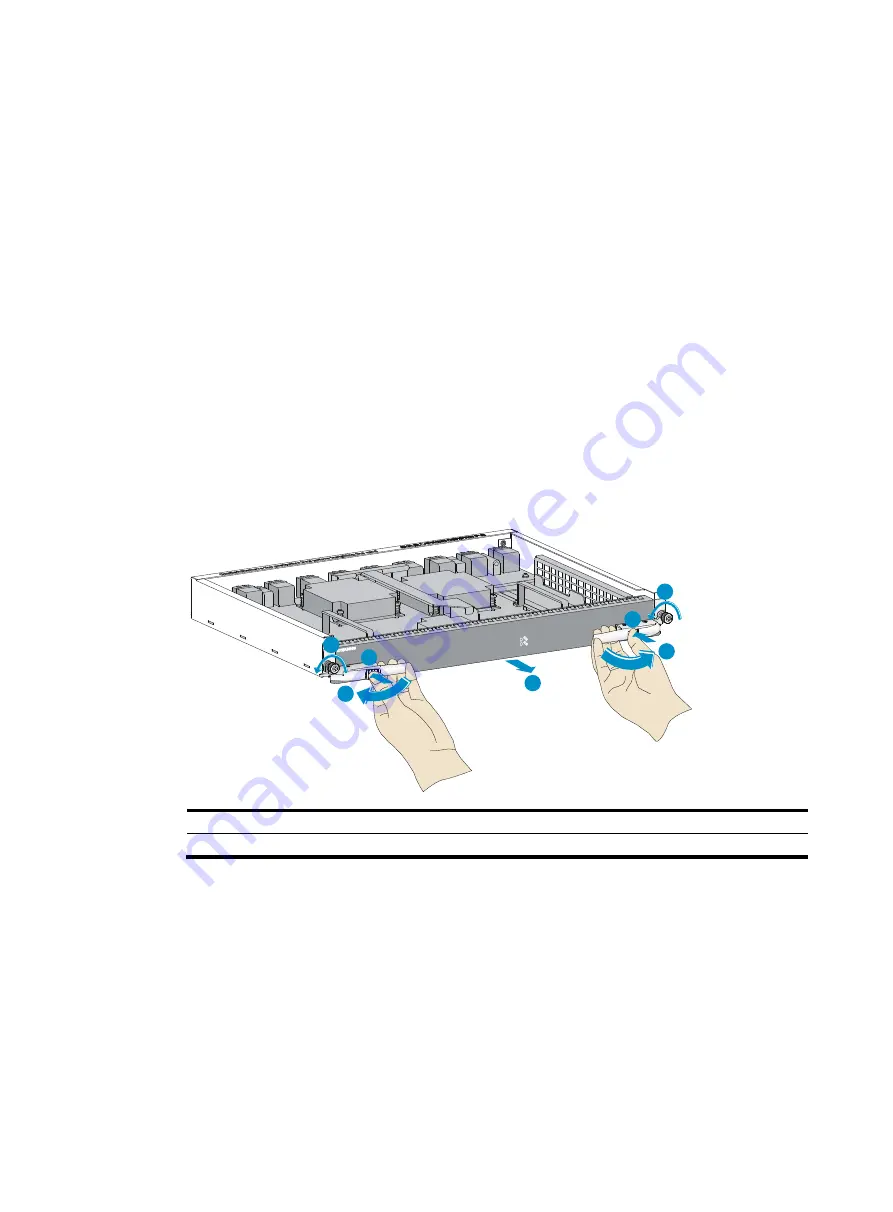

Loosen the captive screws on the protection box, hold the ejector levers on the switching fabric

module, pressing the buttons on the levers, pull the ejector levers outward, and pull out the module

from the protection box. See

.

Keep the protection box for future use.

Figure 20

Removing the protection box

(1) Loosen the captive screws

(2) Press down the buttons

(3) Pull the ejector levers outward

(4) Pull out the switching fabric module

4.

Hold the switching fabric module by the front panel with one hand and support its bottom with the

other. Slide the switching fabric module steadily into the target slot along the guide rails.

Do not touch the components on the PCB.

5.

As shown in callout 1 in

, push the switching fabric module until the brakes on the ejector

levers touch the slot edges tightly.

6.

As shown in callout 2 in

, press the ejector levers inward until the ejector levers touch the

panel tightly and the switching fabric module seats into the backplane

7.

As shown in callout 3 in

, fasten the captive screws on the switching fabric module.

1

1

2

2

3

3

4