13

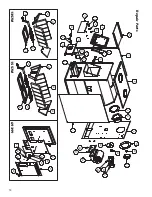

ASSEMBLY OF FURNACE

Your furnace requires the following items to be assembled or

installed by the service person:

Feed Door Pull Handle

Feed Door Locking Handle

Blowers and Blower Controls

Electrical Connections

1. Remove all parts from inside the furnace and inspect for

damage, including the firebrick as some breakage could

occur during shipment.

2. Assemble the Damper Box Assembly to the Feed Door and

the Black Knob to the Damper Box if not already installed.

Ensure the damper operates by sliding the knob up and

down. Damper should operate freely with slight tension.

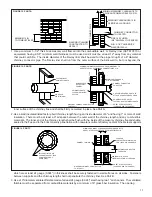

3. Attach feed door locking handle as in Figure 14 with screws

and nuts provided. Note: Slotted holes are for adjustment

of handle. Adjust handle until some pressure is required

to lock feed door during firing sequence.

4. Install the thermodisc on rear of furnace cabinet with the

two screws provided. Mount the conduit assembly from

the junction box to the thermostat bracket. Crimp the two

female terminals to each of the wire leads. Plug the wires

to the thermodisc.

NOTE: It does not matter which of the

two wires plugs to which terminal on the thermodisc.

5. Remove blowers from cartons. Remove junction box

cover. Attach clip nuts as in Figure 15. Install blower(s)

and gasket(s) with 1/4"-20 x 3/4" bolts as shown.

6. Wire right side blower first (See wiring diagram) and replace

cover on junction box on blower.

7. Wire left blower same as above and replace cover.

8. Check operation of shaker grates with grate handle before

operating furnace.

Figure 15

(Model 1357M has only one blower)

Figure 14

Figure 13

THERMODISC

THERMODISC

COVER

4” ELECTRICAL

JUNCTION BOX

BLOWERS

BLOWERS GASKET

CLIP NUTS

(Not used in the upper center hole.)

Summary of Contents for 1357M

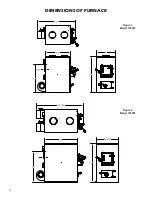

Page 6: ...6 Figure 2 Model 1557M Figure 1 Model 1357M DIMENSIONS OF FURNACE ...

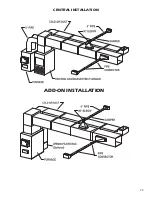

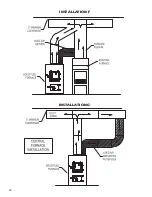

Page 23: ...23 CENTRAL INSTALLATION CENTRAL INSTALLATION ADD ON INSTALLATION ...

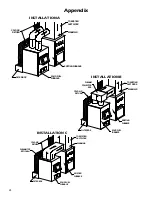

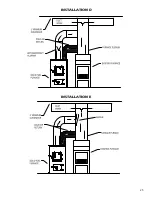

Page 25: ...25 INSTALLATION D INSTALLATION E ...

Page 26: ...26 INSTALLATION F INSTALLATION G ...

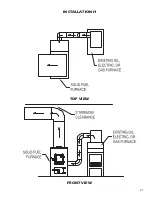

Page 27: ...27 INSTALLATION H TOP VIEW FRONT VIEW ...

Page 30: ...30 NOTES ...

Page 31: ...31 NOTES ...