WT8840 TRADE WATER HEATER CONTROLS

7

34-00013EF—01

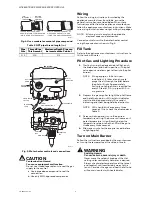

Troubleshooting Without Status Indicator Assistance

Follow diagram in Fig. 6.

Fig. 6. Troubleshooting without status light.

Thermopile Output Check

1.

Turn device knob to OFF.

2.

Disconnect thermopile leads.

3.

Turn device knob to PILOT, hold down knob to

light pilot burner. Hold the knob down for five or

more minutes.

4.

After five minutes, check thermopile output by

connecting the voltmeter to the positive red lead

and negative white lead.

5.

Output should be at least 350 mV. (See Fig. 7.)

Connect the 3.6 ohm resistor between the two

thermopile leads, the voltage should be at or

higher than one half of the open circuit voltage.

6.

The terminal housing prevents miswiring of

positive and negative leadwires.

7.

Flame must envelop thermopile at Hot Junction

(3/8 in. below tip).

8.

Keep heat away from cold junction (brass sleeve

of the thermopile) for maximum output.

Fig. 7. Thermopile output.

TURN DEVICE KNOB FROM OFF TO

PILOT, PRESS DOWN KNOB AND HOLD,

LIGHT PILOT BY DEPRESSING PIEZO

IGNITION BUTTON, PILOT SHOULD

LIGHT.

– WATER TEMPERATURE IS BELOW

THE CUT-OUT LIMIT

CHECK:

• WIRING OF THERMOPILE LEADS

• FLAME COVERAGE OF THERMOPILE

– THERMOPILE OUTPUT IS TOO LOW-RUN

•

THERMOPILE OUTPUT CHECK

STATUS LIGHT SHOULD FLASH AFTER

1 MINUTE, LED WILL FLASH NORMAL

SINGLE BLINK, RELEASE THE DEVICE

KNOB, PILOT SHOULD REMAIN LIT

TURN DEVICE KNOB TO DESIRED

TEMPERATURE SETTING, BURNER WILL

TURN ON ONLY IN ACTIVE CALL FOR

HEAT (WATER TEMPERATURE IS LESS

THAN TEMPERATURE SETTING MINUS

DIFFERENTIAL); LED FLASHES 1 TIME

EVERY 3 SECONDS WHILE IDLE AND

STROBES EVERY 3 SECONDS DURING

A CALL FOR HEAT.

SYSTEM OK

CHECK:

• EXCESSIVE INLET PRESSURE

• TANK TEMPERATURE IS AT OR CLOSE

TO SET POINT

NO

NO

NO

YES

YES

YES

M29431

TROUBLESHOOTING GUIDE WITHOUT STATUS LIGHT

CHECK:

• INLET PRESSURE

• MAKE SURE AIR IS BLED OUT OF SYSTEM

• PIEZO SPARKING TO THERMOPILE

• CLOGGED PILOT ORIFICE

• GAS LEAK IN PILOT TUBING CONNECTIONS

M22535B

TIME (MINUTES)

OUTPUT (mV)

THERMOPILE OUTPUT WITH TIME

500

600

400

300

200

100

0

0

1

2

3

4

5

6

7

8

9

10

900

800

700

NORMAL RANGE

OUTPUT TOO LOW