WT8840 TRADE WATER HEATER CONTROLS

3

34-00013EF—01

WARNING

Fire or Explosion Hazard.

Can cause severe injury, death or property

damage.

Follow these warnings exactly:

1. To avoid dangerous accumulation of fuel

gas, turn off gas supply at the appliance

service valve before starting installation

and perform the Gas Leak Test after

completion of installation.

2. Always install a sediment trap in gas

supply line to prevent contamination of

ignition system control.

3. Follow the appliance manufacturer

instructions if available; otherwise, use

these instructions as a guide.

WARNING

Scalding Hazard.

Can cause burns, severe injury or death.

Always use a direct replacement sensor

assembly when replacing a temperature

sensor.

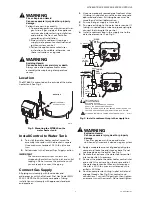

Location

The WT8840 is mounted on the outside of the water

heater tank. See Fig. 2.

Fig. 2. Mounting the WT8840 on the

water heater tank.

Install Control to Water Tank

1.

To install the water heater control, screw the

assembly into spud until the bracket is square.

Use a maximum torque of 31 ft.-lbs. plus one

turn.

2.

Follow steps in the Connect Gas Supply section.

IMPORTANT

These water heater system controls are

shipped with protection for the inlet and outlet

tappings. Do not remove the protection until

you are ready to connect the piping.

Connect Gas Supply

All piping must comply with local codes and

ordinances or with the National Fuel Gas Code (ANSI

Z223.1 NFPA No. 54), whichever applies. Tubing

installation must comply with approved standards

and practices.

1.

Use a new, properly reamed pipe free from chips.

If tubing is used, make sure the ends are square,

deburred and clean. All tubing bends must be

smooth and without deformation.

2.

Ensure that gas supply is turned off.

3.

Run pipe or tubing to the water heater control. If

tubing is used, obtain a tube-to-pipe coupling to

connect the tubing to the control.

4.

Install a sediment trap in the supply line to the

water heater control. See Fig. 3.

Fig. 3. Install a sediment trap in the supply line.

WARNING

Explosion Hazard.

Can cause severe injury, death or property

damage.

Check for gas leaks with soap and water

solution any time work is done on a gas system.

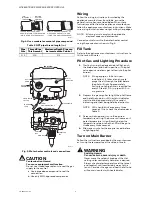

5.

Apply a moderate amount of good quality pipe

compound, leave two end threads bare. Do not

use pipe dope on the outlet. See Fig. 4

6.

Remove the seals over the water heater control

inlet and outlet, if necessary.

7.

Connect the pipe to the water heater control inlet

and outlet. Use a wrench on the square end of

the water heater control. Maximum torque on

the inlet is 40 ft-lbs.; maximum torque on the

outlet is 30 ft-lbs.

8.

Position compression fitting in pilot outlet and

engage threads. See Fig. 5 for controls and

connections. Turn until finger tight, then tighten

one more turn with a wrench. Do not overtighten.

MOUNTING

WELL ASSEMBLY

ACCESS TO TANK

M36123

WT8840

HORIZONTAL

DROP

PIPED

GAS

SUPPLY

3 IN.

(76 MM)

MINIMUM

TUBING

GAS

SUPPLY

HORIZONTAL

DROP

3 IN.

(76 MM)

MINIMUM

RISER

M29522

1

1

WARNING

EXPLOSION HAZARD.

FAILURE TO FOLLOW PRECAUTIONS CAN

RESULT IN A GAS-FILLED WORK AREA.

SHUT OFF THE MAIN GAS SUPPLY BEFORE REMOVING END CAP.

TEST FOR GAS LEAKAGE WHEN INSTALLATION IS COMPLETE.

ALL BENDS IN METALLIC TUBING SHOULD BE SMOOTH.