SP970A, B, C AND D MANUAL AND MINIMUM POSITION PRESSURE REGULATORS

Table 1. Port Identification.

SP970A Pressure

Regulator

SP970A Minimum Position SP970B SP970C, D

SP92

SP93

Main

1

1

1

1

2

M

Pilot

√

4

√

3

4

P

Branch

2

2

2

2

3

B

Exhaust

4

√

4

4

√

√

Calibration

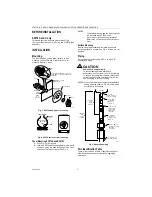

All SP970A and C models are calibrated at 8 psi (55 kPa)

when the calibration mark (center punch) on the shaft is

centered at the bottom of the molded V. To calibrate,

align the center punch mark on the shaft with the bottom

of the molded V groove on the plastic surrounding shaft.

See Fig. 3. This setting equals 8 psi (55 kPa). Secure the

knob to the shaft at the proper scale setting. The knob

should be pointing to 8 psi (55 kPa). See Fig. 4.

All SP970B and D models are calibrated at 8 psi (55 kPa)

when the knob is set at 50 percent.

The large range device can be field recalibrated to other

end points with the same span from 0 psi (0 kPa) lower

limit to 26 psi (179 kPa) upper limit. The small range

device can be field recalibrated to other end points with

the same span from 0 psi (0 kPa) lower limit to 16 psi

(110 kPa) upper limit.

Checkout and Test for All Models

1.

With main air connected, insert a pressure gage

into the branch line.

2.

Check pressures equivalent to knob settings.

3.

When minimum position is used, attach input and

increase pilot pressure.

4.

Verify correct operation.

ENGINEERING DATA

Specifications

Models:

- SP970A: A bleed type pressure regulator.

- SP970B: A bleed type pressure regulator mounted

on a sheet metal panel.

- SP970C: A bleed type pressure regulator with a

dead ended pilot chamber for minimum pressure

applications.

- SP970D: A bleed type pressure regulator with a

dead ended pilot chamber for minimum pressure

applications mounted on a sheet metal panel.

Selectable Spans for psi (kPa):

See Table 2.

Table 2. Selectable Spans.

Model

Knob Rotation

a

188

244

300

Small span

5 (34)

6.5 (45)

8 (55)

Large span

10 (69)

13 (90)

16 (110)

a

The setpoint knob normally rotates 188 degrees. Two

breakaway stops on the knob allow rotation of 244 and

300 degrees.

Operating Pressure (Switch and Pilot) Range:

Normal Main: 18 psi (124 kPa)

Branch: 3 to 15 psi (21 to 103 kPa)

Pilot: 3 to 15 psi (21 to 103 kPa)

Maximum Safe Air Pressure:

30 psi (207 kPa)

Ambient Operating Limits:

Temperature: 0 to 140°F (-18 to 60°C)

Relative Humidity : 5 to 95%

Air Handling Capacity:

SP970A, B: above minimum position, device feeding

pilot determines capacity. Below minimum position,

air capacity is 0.022 scfm (10 ml/s)

SP970C, D: 0.022 scfm (10 ml/s)

Air Consumption:

0.022 scfm (10 ml/s)

Scaleplate:

All models ship with a 0 to 100 scaleplate

(including knob and locknuts).

Construction:

Molded plastic with neoprene diaphragm,

steel spring and shaft.

Operation

SP970A and B: Three Port Switches

PRESSURE REGULATOR OPERATION

Main line air flows through the restriction into the

branchline chamber and out the nozzle. Branchline

pressure increases until it is strong enough to compress

the spring and lift the diaphragm off the nozzle. Airflow

out the nozzle is controlled by the balance between the

branchline pressure and spring force.

MINIMUM POSITION OPERATION

An external signal is connected to port 4 (exhaust port).

When the external signal is greater than the spring load,

the nozzle opens and branchline pressure is the same as

the external signal. When the external signal is less than

the spring load, branchline pressure is controlled as

described in the previous paragraph. See Fig. 6.

SP970A,B

4

SP970A,B

2

2

BRANCH

BRANCH

1

PILOT

MAIN

PILOT

MAIN

4

C4298

Fig. 6. SP970A/B operation.

3

95-7237EF

1