Honeywell GmbH

9

MU1H-1547GE23 R1009

GB

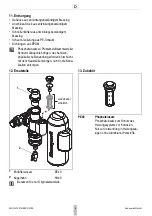

10.2 Clean quick bleeder

1. Put the heater system out of operation

2. Close the stop valves ahead and following the

sludge and air separator

3. Place a suitable, heat-resistant container under-

neath

4. Release the pressure in the sludge and air sepa-

rator by opening the lower ball valve

5. Unscrew and clean the quick bleeder

6. Reassemble in reverse order

10.3 Replace the phosphate cartridge (available as

an accessory).

1. Put the heater system out of operation

2. Close the stop valves ahead and following the

sludge and air separator

3. Place a suitable, heat-resistant container under-

neath

4. Release the pressure in the sludge and air sepa-

rator by opening the lower ball valve

5. Unscrew the phosphate cartridge counter-clockwise

using a spanner (SW 27)

6. Dispose of the phosphate cartridge (see chapter 11)

7. Screw in a new phosphate cartridge in clockwise

direction into the sludge and air separator

o Tighten not too tightly

8. Open the stop valve ahead of the sludge and air

separator to rinse out any possible foreign particles

through the lower ball valve

9. Close the lower ball valve again

10.Slowly open the stop valve following the sludge and

air separator

11.Put the heater system back into operation

12.Refill heater system if necessary

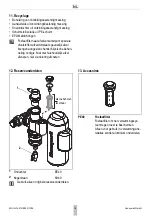

10.4 Cleaning the magnetic separator

The integrated magnetic separator serves to reliably

separate ferromagnetic metals in the heater system.

The blind plug included in the scope of delivery

contains the magnetic separator.

1. Put the heater system out of operation

2. Close the stop valves ahead and following the

sludge and air separator

3. Place a suitable, heat-resistant container under-

neath

4. Release the pressure in the sludge and air sepa-

rator by opening the lower ball valve

5. Screw out the blind plug (SW27)

o If the phosphate cartridge is installed, take off the

filter basket

6. Clean the magnetic separator integrated in the blind

plug from all collected particles

7. Screw the blind plug in with not too much force

8. Open the stop valve ahead of the sludge and air

separator and rinse out the filter to clean out any

foreign particles through the lower ball valve

9. Close the lower ball valve again

10.Slowly open the stop valve following the sludge and

air separator

11.Put the heater system back into operation

12.Refill heater system if necessary

11. Disposal

• Dezincification resistant brass housing

• Connection piece made of dezincification-resistant

brass

• Quick bleeder made of dezincification-resistant

brass

• Foam insulation made of PE foam

• EPDM sealing washers

The quick bleeder can become leaky from

washed-in or hoiked dirt particles.

Depending on the composition and the quality

of the heater water, are periodic maintenance

by a technician becomes necessary.

The filtering of the corrosion protection agents

makes it necessary to replace the phosphate

cartridge every year.

Danger of scalding from hot heater water!

Observe the material safety data sheet

(included in the scope of delivery of the phos-

phate cartridge).

Due to corrosion reasons, the magnetic sepa-

rator should be cleaned regularly.

Do not use any chemical cleaners.

Take the phosphate cartridge to an hazardous

waste collections point / disposal plant,

because chemical and physical treatment is

necessary. Do not dispose of with household

waste and do not pour into the sewage