MU1H-1547GE23 R1009

7

Honeywell GmbH

GB

1. Safety Guidelines

1. Follow the installation instructions.

2. Use the appliance

• according to its intended use

• in good condition

• with due regard to safety and risk of danger.

3. Note that the appliance is exclusively for use in the

applications detailed in these installation instruc-

tions. Any other use will not be considered to comply

with requirements and would invalidate the

warranty.

4. Please take note that any assembly, commis-

sioning, servicing and adjustment work may only be

carried out by authorized persons.

5. Immediately rectify any malfunctions which may

influence safety.

6. Arbitrary changes are not permitted for safety

reasons. Original parts and accessories have been

designed especially for this device and can be

acquired from sanitation wholesalers.

7. The manufacturer is in no way liable for damages

that result from modifying the sludge and air sepa-

rator or usage of not original parts.

2. Functional description

The sludge and air separator serves to separate

sludge and air from the heater system.

It is equipped with a sludge and contamination reduc-

tion that functions according to the cyclone principle.

This guarantees an effective separation of the

particles.

The sludge and air separator is equipped with a quick

bleeder for the air separation. If there is air in the

system, it will rise to the highest point of the sludge and

air separator. The water level drops there, the inte-

grated floater pulls the floater arm down and thereby

opens the sealed area. The air bleeds out whereby the

water level rises again and the sealed area is closed

again.

The optionally available phosphate cartridge counters

the corrosion in the heater system. This dosing serves

as an additional protection of the heater system; not as

a replacement of the basic conditioning of the heater

water by inhibitors.

3. Application

The sludge and air separator is installed in the heating

circuit (feed and return line) and serves to separate

sludge and air from the heater water.

4. Technical data

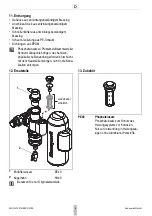

5. Scope of delivery

The sludge and air separator consists of:

• Housing

• Connection piece incl. couplings and seals

• Quick bleeder

• Blind plug including magnetic separator

• Foam insulation jacket

• Ball valve

6. Options

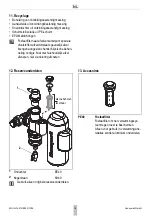

7. Assembly

7.1 Installations Guidelines

• The sludge and air separator is not suited for:

o the separation of oils greases, solvents, soaps

and other lubricating media

o the separation of water-solvent materials

• The sludge and air separator is installed in the

heating circuit (feed and return line)

• The heating system needs to be rinsed and filled

• The national installation regulations, general guide-

lines and technical data must be observed during

the assembly

• The installation site has to be frost-free and the

protection of the device from chemicals, paints,

solvents, vapours and environmental influences

must be guaranteed

• A course dirt separator needs to be installed up front

for water with course dirt particles

• To ensure the bleeding of the air, the sludge and air

separator has to be installed with the quick bleeder

upwards

• The separator has to stand vertically; the connec-

tion piece can be built into horizontal and vertical

lines

• Make sure the seals fit properly. The pressure-

sealing tightening of the screws has to be done

cross-wise

• Install stop valves ahead and following the sludge

Connection diameter

DN25

Nominal pressure (PN)

10 bar

Operating pressure

max. 10 bar

Nominal flow

3,6 m³/h

Pressure loss during nominal flow rate 0,2 bar

k

vs

-value

7,8 m³/h

Operating temperature

max. 90°C

HF49-1A= Standard version