L8148A,E,J AQUASTAT® RELAYS

5

60-2278—9

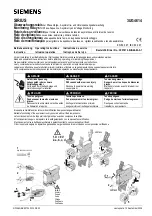

8.

Fit the case onto the well so the clamp on the case

slides over the flange on the well. Tighten the clamp

screw securely.

IMPORTANT

Best thermal response is obtained with a well that

snugly fits the sensing bulb. For wells used, the bulb

should be inserted until it rests against the bottom of

the well. Use a well of correct length and bend the

tubing, if necessary, to hold the bulb against the

bottom of well, but do not make a sharp bend in the

tubing.

If the well does not fit snugly on the bulb, use the heat-

conductive compound (furnished with TRADELINE® models)

as follows: Fold the plastic bag of compound lengthwise and

twist it gently. Then snip off the end of the bag and work the

open end of the bag all the way into the well. Slowly pull out

the bag while squeezing it firmly to distribute the compound

evenly in the well. Insert the bulb all the way to the bottom of

the well. Bend the tubing, if necessary, to hold the bulb

against the bottom of the well and to hold the outer end of the

bulb firmly in contact with the side of the well (Fig. 4). Wipe

excess compound off the outer end of the well.

Mounting (TRADELINE® Models)

If the old well is suitable, use it and an immersion well adapter

(see Accessories) for the installation; otherwise, refer to the

standard mounting procedure. (Well assemblies for the

TRADELINE® Aquastat® Relays must be ordered separately;

refer to form 68-0040, Wells and Fittings for Temperature

Controllers.) The adapter has a flange at the wide end that fits

into the well clamp and is slotted lengthwise to accommodate

both the capillary tube and the short length of tube extending

from the bulb (Fig. 4).

1.

Turn off all power and remove the old control. Tag each

external leadwire using the cover insert from the old

control.

2.

Loosen but do not remove the well clamp screw on the

side of the control case.

3.

Pull out the capillary tube until it bottoms in the well.

Place the adapter around the capillary tube so it fits into

the slot. Center the loop of excess capillary tubing in

front of the immersion well so it cannot touch any

electrical parts.

NOTE: Some models have a tubing length adjustable to 3 in.

(76 mm). In these models, extra tubing inside the

case can be pulled out, if needed.

4.

Make sure the wide end of the adapter fits into the hole

in the case. Position the immersion well clamp snugly

over the flange on the adapter and tighten the clamp

screw.

5.

Insert the sensing bulb into the well as shown in

Fig. 4. (Distribute heat-conductive compound prior to

insertion.)

6.

Securely tighten setscrew (if present on old well)

against adapter.

Wiring

IMPORTANT

Terminals on the L8148 Aquastat¨ Relay are

approved for use with only copper wire. The

terminals allow only wrap-around wiring.

1.

Strip 7/16 in. of insulation

from the wire end.

2.

Wrap the wire at least 3/4 of

the distance around the screw

as shown.

3.

Using a standard, flat-headed

screwdriver, tighten the screw

until the wire is snugly in

contact with the screw and contact plate.

4.

Tighten the screw an additional one-half turn.

NOTE: Do not use a push-type ratchet screwdriver.

Disconnect power supply before making wiring connections to

prevent electrical shock or equipment damage.

All wiring must comply with local electrical codes and

ordinances. Do not exceed limits in the Specifications section

when applying this control.

When wiring a switch equipped with 1/4 in. tab terminal

connector, use 18 to 22 gauge wire with AMP Inc. part no.

2-520129-2 fully insulated flag receptacle connector or

equivalent.

The L8148E,J can power up to two V8043 Zone Valves.

Additional valves, in groups of two or fewer, require an

additional transformer. Follow appropriate wiring diagrams,

see Fig. 5 through 14, when using zone valves or a low limit

controller.

NOTE: On systems requiring a vent damper, the vent

damper can be connected directly to some L8148E

Aquastat® Relay models (Fig. 12) or an S8610

Ignition Module (Fig. 11).

When the vent damper is plugged into the Aquastat¨ Relay, a

fuse in the Aquastat¨ Relay will blow when the thermostat first

closes. Once the fuse is blown, the Aquastat¨ Relay will not

operate unless the vent damper is connected.

When the vent damper is plugged into the Aquastat¨ Relay, a

fuse in the Aquastat¨ Relay will blow when the thermostat first

closes. Once the fuse is blown, the Aquastat¨ Relay will not

operate unless the vent damper is connected.

With the vent damper plugged into the S8610, a fuse in the

ignition module will blow when first powered. Once the fuse is

blown, the ignition module will not operate unless the vent

damper is connected.

M8843