GB

MU0H-1155GE23 R0319

3

Fine filter:

Pressure reducing valve:

5

Options

The water station is available in the following sizes: DN65,

DN80 and DN100.

• standard

- not available

Note:

... = space holder for connection size

Note:

Ordering number example for DN65 and type FA valve:

HS10S-65FA

6

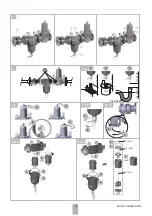

Assembly

6.1 Installation Guidelines

•

Install in horizontal pipework with test and drain plugs

and filter bowl downwards and spring bonnet upwards

–

This position ensures optimum draining and filter

efficiency

•

Install shut-off valves

–

Shut-off valves provide optimal serviceability

•

Ensure good access

–

Pressure gauge can be read off easily

–

Simplifies maintenance and inspection

•

The installation location should be protected against

frost

•

Fit immediately after water meter

–

Corresponds to DIN 1988-2

•

Provide a straight section of pipework of at least five

times the nominal valve size after the pressure reducing

valve (in accordance with EN 806-2)

6.2 Assembly instructions

1.

Thoroughly flush pipework

2.

Install pressure reducing valve

•

Note flow direction

•

Install without tension or bending stresses

3.

Seal in pressure gauges

6.3 Discharge of reverse rinsing water

CAUTION!

According to EN1717 the space between bottom

from discharge connection at the filter and the

sewage piping (e.g. drain connection with syphon)

has to be 56mm at least.

To do this there are 3 options:

1.

Discharge into floor drain

2.

Drain into open container.

3.

Discharge into drain connector with syphon (min.

DN70)

*at 4.0 bar inlet pressure and 22 s reverse rinsing duration

- operated by actuator or at 4 bar inlet pressure and 3x 3 s

rinsing duration - operated by hand.

Components

Materials

1

Pressure gauge

Metal

2

Housing and filter bowl

Ductile cast iron (EN-GJS-

400-15 EN 1563), coated

with PA (polyamide)

3

Fine filter

Stainless steel

4

Ball valve with lever and

drain connection

Ball Valve body: Brass

chrome plated

Ball: Brass chrome plated

Drain adapter: Plastic

Not depicted components:

Inner parts

Stainless steel, brass and

plastic

Components

Materials

1

Housing with PN16 flanges

per ISO 7005-2, EN 1092-

2

Ductile cast iron (EN-GJS-

400-15 EN 1563), coated

with PA

2

Pressure gauge

-

Not depicted components:

Adjustment spring

Spring steel

Cartridge insert

Completely of low-lead

(<2.2 % acc. to DIN 50930-

6) brass with stainless

steel valve spindle

Diaphragm and seals

EPDM

Groove ring and sealing

disc

EPDM

Thread rod and nuts

Stainless steel

Spring bonnet with

adjustment screw

Ductile cast iron (EN-GJS-

400-15 EN 1563), coated

with PA

HS10S-

...FA

Connection

type:

Standard version with flanges

PN16, filter mesh size 100

µ

m

•

Filter size

Reverse rinsing volume*

DN65 - 100

55 litre