GB

2

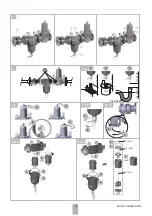

MU0H-1155GE23 R0319

1

Safety Guidelines

1.

Follow the installation instructions.

2.

Use the appliance

•

according to its intended use

•

in good condition

•

with due regard to safety and risk of danger.

3.

Note that the appliance is exclusively for use in the

applications detailed in these installation instructions.

Any other use will not be considered to comply with

requirements and would invalidate the warranty.

4.

Please take note that any assembly, commissioning,

servicing and adjustment work may only be carried out

by authorized persons.

5.

Immediately rectify any malfunctions which may

influence safety.

2

Description of Function

Spring loaded check valves have a moving seal disc which is

lifted off the seat by a greater or lesser amount depending on

the flow rate through the valve. If the flow falls towards zero,

then the spring pushes the disc back onto the seat and seals

the waterway.

To ensure continuing correct function it is recommended that

check valves be regularly checked and maintained (as

specified in EN 1717).

The filter insert is divided into two parts. In the „filtering“

position, only the lower, larger section is used for filtering. The

small upper section does not come in contact with unfiltered

water. An oscillating flap integrated in the sieve prevents the

deposition of dirt particles on the upper part of the filter. When

the ball valve is opened for reverse rinsing, then the whole

filter insert is pushed downwards until the water supply to the

outer side of the main filter is stopped. Simultaneously, the

water flow is opened to the upper part of the filter. The water

needed for cleaning the filter passes through the upper filter

section, then the rotating impeller with jets and the main filter

from inside to outside, i.e. the filter is reverse rinsed with

filtered water. The filter automatically switches back to the

operating position when the ball valve is closed again.

Spring loaded pressure reducing valves operate by means of

a force equalising system. The force of a diaphragm operates

against the force of an adjustment spring. If the outlet

pressure and therefore diaphragm force fall because water is

drawn, the then greater force of the spring causes the valve

to open. The outlet pressure then increases until the forces

between the diaphragm and the spring are equal again.

The inlet pressure has no influence in either opening or

closing of the valve. Because of this, inlet pressure fluctuation

does not influence the outlet pressure, thus providing inlet

pressure balancing.

3

Technical Data

4

Scope of Delivery

Check valve:

Media

Medium: Drinking

water

Connections/Sizes

Connection sizes:

DN65 - DN100

Pressure values

Max. operating pressure:

2.0 - 16.0 bar

Outlet pressure:

1.5 - 7.5 bar

Inlet pressure:

max. 16 bar

Nominal pressure:

PN16

Min. pressure drop:

1.0 bar

Opening pressure check

valve:

ca. 0.05 bar

Operating temperatures

Max. operating temperature

medium:

65°C (max. operating

pressure 6.0 bar)

Specifications

Installation position:

Horizontal with filter bowl

downwards

Flanges on inlet and outlet: Flanges PN16 acc. to DIN

86021 / ISO 7005-2, EN

1092-2

Components

Materials

1

Housing and housing end

casing with flanges

Grey cast iron coated with

PA (polyamide)

Not depicted components:

Check valve insert

Stainless steel

Test and drain plugs

Stainless steel

Screws and nuts

Stainless steel

Disc

Stainless steel

Spring

Stainless steel

Lip seal ring

EPDM