GB

4

MU0H-1155GE23 R0319

7

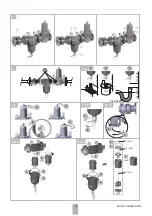

Start-up

7.1 Setting outlet pressure

Set outlet pressure min. 1 bar under inlet pressure.

1.

Close shut-off valve on inlet

2.

Release pressure on outlet side (e.g. through water tap)

3.

Close shut-off valve on outlet

4.

Loosen slotted screw

•

Do not remove slotted screw

5.

Slacken tension in compression spring

•

Turn adjustment handle counter clockwise (-) until

it does not move any more

6.

Slowly open shut-off valve on inlet

7.

Turn control handle until the setting scale shows the

desired value

8.

Re-tighten slotted screw

9.

Slowly open shut-off valve on outlet

7.2 Reverse rinsing

CAUTION!

Interval:

at least every 6 month (acc. to EN806-5)

every 2 months (manufacturer's recommendation)

resp. depending on the degree of dirt in the water.

Red pointer integrated into the view window of one of

the pressure gauges for setting the next reverse

rinsing

Date for next reverse rinsing can be set at the memory

indicator of the outlet pressure gauge.

To ensure convenient and regular adherence to the

reverse rinsing interval, we recommend installing an

automated reverse rinsing system Z11AS.

During reverse rinsing, an inlet pressure of at least

1.5bar is required.

Filtered water can also be tapped during reverse

rinsing.

To avoid extra abrasion, we recommend to perform the

backwash at operating inlet pressures below 12 bar.

7.2.1 Manual reverse rinsing

A collecting container must be positioned beneath

before reverse rinsing if there is not drainage system

available.

1.

Slowly open the ball valve

•

The patented reverse rinsing system starts

2.

Close ball valve again after approx. 3-5 seconds.

Repeat procedure three times

•

If the filter is extremely dirty, the procedure may

have to be repeated additional times

7.2.2 Automatic reverse rinsing with the

Z11AS

The automated reverse rinsing system Z11AS is available as

an accessory. The automated system reliably takes over

reverse rinsing of the filter at intervals which can be set

between 4 minutes and 3 months.

7.2.3 Differential pressure controlled

reverse rinsing with the DDS76 and

Z11AS

Also available as an accessory is the DDS76 differential

pressure switch. It provides fully automatic operation of the

reverse rinsing which is controlled by the differential pressure

across the filter. It actuates a reverse rinsing cycle when the

pressure differential between the inlet and outlet of the filter

reaches a predetermined value. If the pressure difference

exceeds the preset value, then the Z11AS reverse rinsing

actuator is operated via its volt-free input.

8

Maintenance

8.1 Inspection

We recommend taking out a servicing contract with an

installation firm

In accordance with EN 806-5, the following measures

must be taken:

8.1.1 Check valve

Interval: once a year

1.

Close shut-off valve on inlet

2.

Open test valve

•

Until the pressure is released, some water will flow

out of the test valve. After a short period of time the

water flow should stop. If the water continues to

drip or run, then the check valve must be replaced

- see servicing of check valve

3.

Close test valve again

4.

Slowly open shut-off valve on inlet

8.1.2 Filter

CAUTION!

Interval:

at least every 6 month (acc. to EN806-5)

every 2 months (manufacturer's recommendation)

resp. depending on the degree of dirt in the water.

An increased differential pressure between inlet and

outlet pressure gauge indicates a highly contaminated

filter.