43

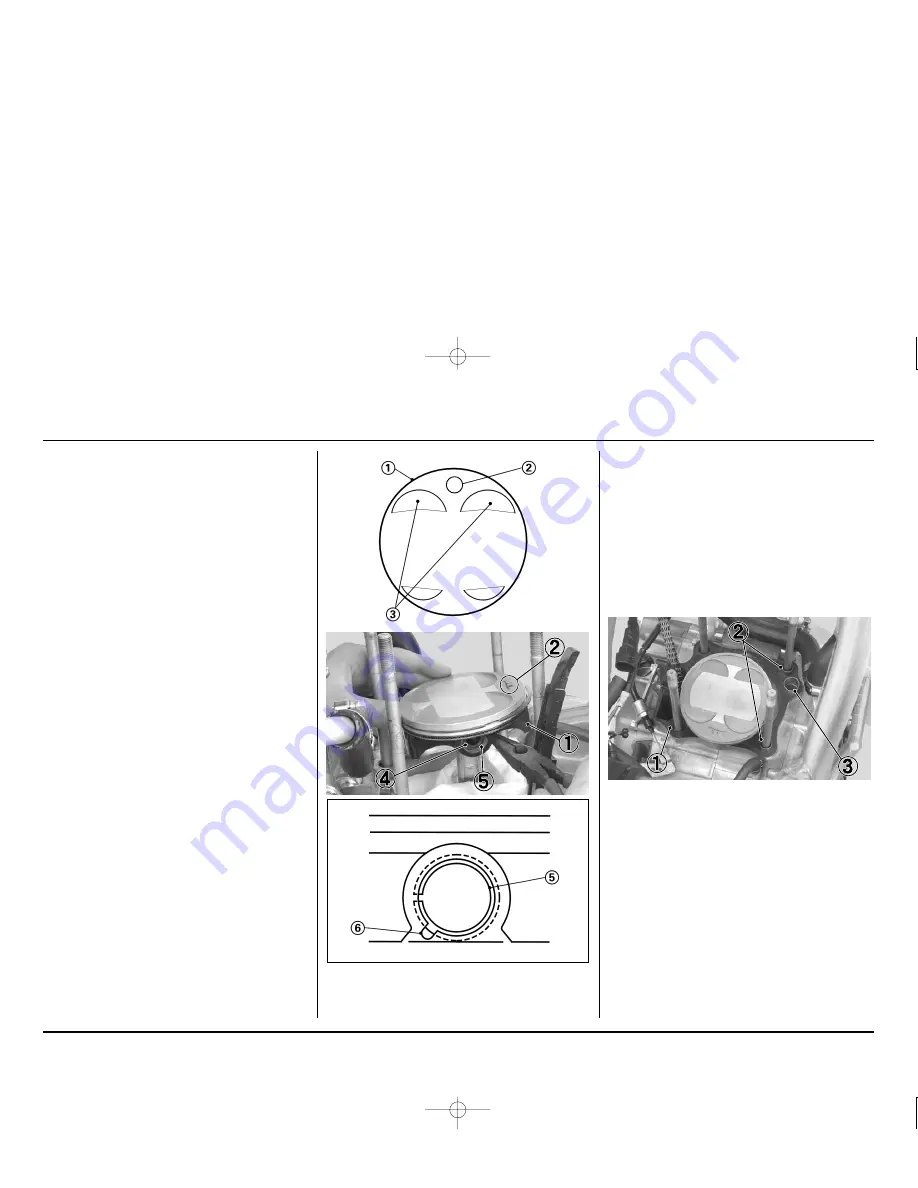

Piston Installation

Place clean shop towels in the crankcase to keep the

piston pin clips from falling into the crankcase.

Apply molybdenum disulfide oil (a mixture of 1/2 en-

gine oil and 1/2 molybdenum disulfide grease (con-

taining more than 3% molybdenum disulfide additive))

to the connecting rod small end.

Install the piston with the “IN” mark and/or the large

valve recesses facing the intake side of the engine.

Apply flesh engine oil to the piston pin.

Install the piston pin and new piston pin clips.

CAUTION:

•

Use new pin clips. Never reuse old clips.

•

Do not let the clips fall into the crankcase.

•

Do not align the piston pin clip end gap with the

piston cut-out.

(1) PISTON

(2) “IN” MARK

(3) LARGE VALVE RECESSES

(4) PISTON PIN

(5) PISTON PIN CLIP

(6) CUT-OUT

Cylinder Installation

Clean off any gasket material from the gasket surface

of the crankcase, being careful not to let any material

fall into the crankcase.

NOTE:

•

Be careful not to remove any metal from the gasket

surface.

Remove the shop towel. Do not let any gasket debris

fall into the crankcase.

Install cylinder gasket, A dowel Pins and B dowel pin.

CAUTION:

•

Do not let the dowel pins fall into the crankcase.

(1) CYLINDER GASKET

(2) A DOWEL PINS

(3) B DOWEL PIN

Clean the any gasket material off the cylinder.

IN