44 | EngliSH

Installation information

Caution! The following measures will achieve a safe-

ty level of SIL2, as ignition monitoring measure for

prevention of the coming into effect of a potential

source of ignition, for normal operation of the equip-

ment for the equipment group II and Category II. (ap-

plies only for units with AM303; AM376; AM421 mo-

tors) THE OPERATOR OF THE PLANT must obtain for

the adherence to the ignition protection an own inde-

pendent installation consisting of a combination of

an electro-mechanical actuating system (level regu-

lation) in order to guarantee the required minimum

coverage of the pump hydraulics of at least 0.2 m.The

level safety system must verify a safety integrity level

SIL2!

Before first start-up of the equipment, the level re-

gulation is to be tested as a safety system SIL2 and

approved for function and accuracy according to

the setting parameters. The control of the plant is

to be arranged such that an automatic repeat swit-

ching-on lock after a switch-off of the equipment via

the level regulation, automatically sets the automatic

switching-on of the plant out of action. Only after

successful finding and repairing the error may the

plant be manually put into operation again.

The optical and acoustic warning messages of the

level regulation must be designed according to ergo-

nomic principles and provided unmistakable and cle-

ar information to the operator so that the necessary

measures for avoiding

potential sources of ignition

can be initiated with a high degree of safety.

Caution! The function and effectiveness of the leveli-

ng adjustment must be monitored at regular interva-

ls. A complete inspection must be carried out at last

every 3 months!

The

submersible motor series AM ....../...EX

are cooled

by means of the pumping medium and are suited for con-

tinuous operation S1 with fully covered motor. The motor

part must be fully submerged in order to prevent the sur-

face temperature rising above the temperature classifica-

tion stated on the rating plate. However, with tight pump

shafts, a time of max 10 min can elapse until a level of 0.2

m over the pump part is emptied.

The

submersible motor series AM ....../...UEX

is cooled

by means of a by-pass part flow of the pumping medi-

um. Here, too, the pump part must be fully submerged

in order that the surface temperature does not rise above

the temperature classification stated on the rating plate.

The connection of free ends of the power cable may only

be carried out inside the potentially explosive areas by

means of suitable ex-tested and certified terminal boxes.

No certified terminal boxes need be used outside of po-

tentially explosive areas. A connection with minimum 4

mm2 must be installed to the submersible motor pumps

for the potential equalization according to EN 60079-14.

The cable is connected to this by means of lugs and screw

security of the connection must not be self-loosening. All

existing thermal, level and detector sensors must connec-

ted according to the instructions of this manual and the

accompanying circuit diagram.

Special conditions for safe operation

For the converter operation it is necessary to have an ar-

rangement for direct temperature monitoring. This con-

sists of a PT thermistor built into the coil according to DIN

44 082 with switching temperature according to Table 1

and a function-tested triggering device according to RL

94/9/EG. The switching is to be designed such that when

reaching the limiting temperature, the submersible motor

is switched off and a renewed start-up of the submersib-

le motor is only possible manually! When checking the

gaps of the pressure-tight enclosed motor, it is absolutely

necessary to contact the manufacturer of the submer-

sible motor in order to obtain the gap dimensions.

The

gap of the tested submersible motor is less than that

prescribed by the standards.

The fastening bolts of the motor are special bolts of

stainless steel type A2-70.

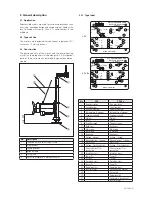

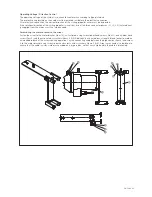

8.5 Installation and start-up of explosion-protected

submersible motors

General information

Caution! Before starting any activity at the site of the

equipment, it is important to obtain knowledge on the

status of the danger of explosion from the user. The

danger potential can be estimated on the basis of of-

ficial zone allocation or an existing explosion protec-

tion document. Possibly a comparison should be

made between the ex-ignition type of the equipment

and the given requirements. In the case of enclosed

spaces of shafts, sufficient ventilation must be ensu-

red before starting work in order to thus prevent the

existence of explosive gases.

HOMA explosion-protected equipment must only be

used in areas (potentially explosive atmospheres)

which are applicable for their declared equipment

group II and category 2G, as well as maximum sur-

face temperature of 135°C for temperature classifi-

cation T4 (for frequency converters operation 200°C

for temperature classification T3) in accordance with

IEC 60079-0 for gases and explosion groups A and B.

Installation information for the electrical part

Caution! It is absolutely necessary that, in addition to

this instruction manual, attention is also paid to the

information in the EU type examination certificate in

the Appendix as is mentioned here again.

8.5.1. Electrical connection

The connection of the power cables may only be carried

out inside the potentially explosive areas by means of sui-

table ex-tested and certified terminal boxes.

8.5.2. Monitoring arrangements

Additional and monitoring arrangements with suitable ve-

rification and explosion protection labeling are to be selec-

ted according to the conditions at site. Monitoring units

must satisfy the requirements of the ATEX 100a, Appen-

dix II, Sections 1.5.5 and EN 1127-1 (potentially explosive

atmospheres - Explosion protection - Part 1: Fundamen-

tals and methods).

Summary of Contents for CHRS.../4 series

Page 25: ...DEUTSCH 25 Notizen Notes ...

Page 71: ...Nedlerlands 71 Notizen Notes ...

Page 75: ...75 ...