32 | EngliSH

3.3.5. Propeller

A self cleaning propeller from stainless steel is used.

3.3.2. Motor

The three-phase asynchronous motor is made from sheet

metal with a double-varnished winding wire as well as the

motor shaft with rotor package. The power supply cable is

designed for the maximum mechanical load and is sealed

against water pressure from the pumped liquid. The mo-

tor cable lead connections are sealed from the pumped

liquid as well. The bearings used are permanently lubricat-

ed maintenance-free antifriction bearings.

All models are available with explosion proof motors.

General motor data

Operating mode

S1

Insulation class

F (155°C)

Degree of protection

IP68

Cable length

10 m

Shaft sealing HRS

NBR

Bearing

one grooved ball bearing (suspension side)

one double-row type angular ball bearing

(propeller side)

3.3.3. Control devices

The pump is equipped with various safety and control de-

vices:

Temperature Sensors

The mixers have a set of temperature sensors built in the

stator windings.

Standard models have the sensors connected to the mo-

tor power supply cable, the wire ends marked T1 and T3.

They must be connected to the safety circuit of the con-

trol box in order to provide an automatic re-start of the mo-

tor, when the motor cools. Explosion proof models with

motors up to 15 kW have a set of temperature sensors

built-in, with a higher switch-off temperature, connected

to the motor cable, the wire ends marked T1 and T2. They

must be connected to a special relay in the starter box in

order to provide manual pump re-start. All explosion proof

models have both sets of sensors built-in, as described

above, with wire ends marked T1, T2, T3. They have to be

connected accordingly as described above. The tempera-

ture sensor set must be connected to the switchgear unit

so that it switches off if it overheats.

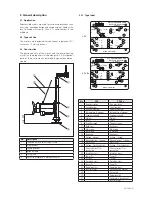

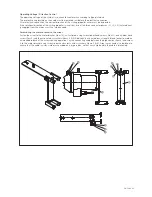

Check of Direction of Rotation

After the electrical connection has been made, check that

the agitator propeller is rotating in the correct direction.

As seen from the motor, the propeller must rotate clock-

wise. If you ordered a special version with left-hand drive,

the propeller must turn counter-clockwise. If the direction

of rotation of the agitator propeller is incorrect, transpose

two of the three conductor phases (L1, L2, L3) coming

directly from the mains.

Beware of rotating propeller!

The moving propeller can crush and sever limbs.

Switch off the machine and let the moving parts

come to a rest before maintenance or repair work!

Seal condition sensors oil chamber

Agitator motors in the HRS…/C and CHRS…/C series are

fitted as standard with monitoring of the sealing of the oil

barrier chamber. Two sensors monitor the conductibility

of the oil filling. The sensors are to be connected via the

connecting cables with the cable-end designations S1 and

S2 in the switchgear to an evaluation instrument with a

galvanically isolated sensor circuit (electrode relay). If the

shaft seal leaks, water enters the oil chamber and chang-

es the resistance of the oil. Response sensitivity should

be adjustable from 0-100 kÙ. The standard setting is 50

kÙ. If this is an antiexplosion design, select electrode re-

lays with intrinsically safe circuits for sensors.

Motor cooling

They are cooled by the surrounding liquid.

Summary of Contents for CHRS.../4 series

Page 25: ...DEUTSCH 25 Notizen Notes ...

Page 71: ...Nedlerlands 71 Notizen Notes ...

Page 75: ...75 ...