ASSEMBLY

HOLZMANN MASCHINEN GmbH www.holzmann-maschinen.at

Seite 40

METALLDREHMASCHINE / METAL TURNING LATHE ED 1000N / ED 1000NDIG

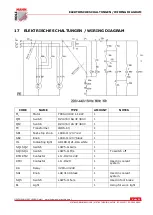

50 Hz

<44 m

2,5 mm

2

<70 m

4,0 mm

2

<105 m

6,0 mm

2

Plug 400V:

5-wire:

with

N-conductor

4-wire:

without

N-conductor

13.3.1

Lubrication

Check the lubrication of the following parts before working on the machine:

13.3.2

Headstock

The bearing of the spindle is situated in an oil bath. Make sure that the oil level is always reached

the mark of the sight glass. To change the oil you drain the oil through development of remote

drain plug at the bottom of the headstock. To replenish the oil again, remove the cover of the

headstock. Check the oil level regularly. The first oil change should be performed after 3 months,

then you should change the oil once a year. (see 15.1.1)

13.3.3

feed gear

The first oil change should be made after three months, after a sufficient change once a year.

(see 15.1.1)

13.3.4

Lock case

The oil bath is filled with Shell Tellus 32. Check the oil level using the oil sight glass on the front

page. The first oil change should be made after three months, then changes once a year is

sufficient. To drain the oil, remove the drain plug at the bottom of the skirt. (see 15.1.1)

13.3.5

Other parts

Additional lubrication points can be found on the drive shaft, the hand wheels to the lock case and

the tailstock. Lubricate them regularly with a grease gun.

Apply a thin coat of oil on the machine bed and all other exposed parts like on the tailstock, screw

cutting, etc. once a day.

13.3.6

Retraction prior to initial

The retraction should be performed with the lowest screw speed. Let the machine at this speed

for about 1 hours walk. Check out irregularities, such as unusual noises, imbalances, etc. If

everything is ok, you gradually increase the speed. The highest speeds may be driven only after

10 hours of operation.

Summary of Contents for ED 1000GDIG

Page 89: ......