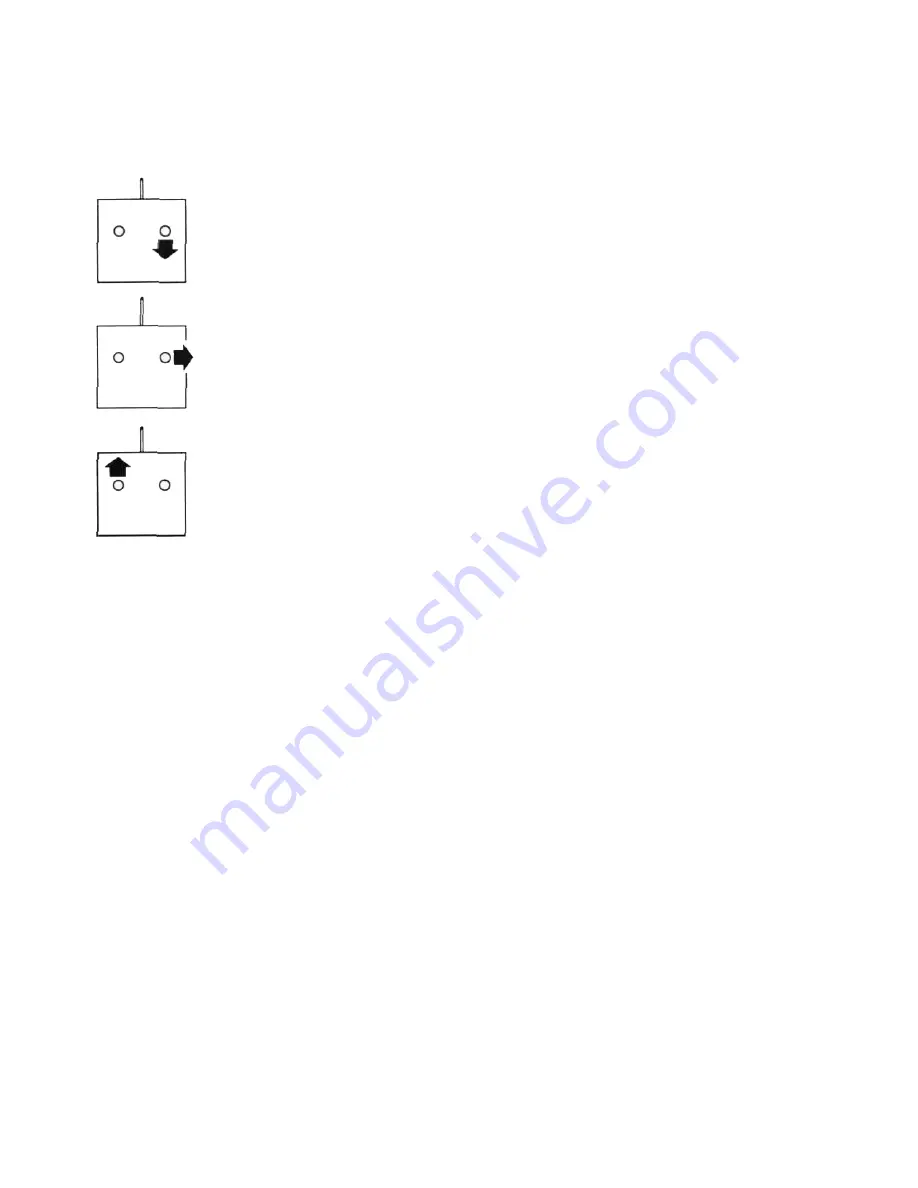

C. The throttle is closed almost all the way when

the left transmitter stick is down (back) and is

open completely when the stick is up (forward).

TRANSMITTER

STICK MOVEMENTS

CONTROL SURFACE

MOVEMENTS

ELEVATOR MOVES UP

RUDDER MOVES RIGHT

CARBURETOR WIDE OPEN

D 67. Check to make sure that the tail control surfaces

are in a neutral (straight) position and the servo arms are

perpendicular to the aluminum channel when the

transmitter sticks at neutral. Also check the control

throws on the tail surface. You should be able to move

the rudder 3/4" both directions and the elevator should

move 1/2" both directions. This should give you a plane

that is fairly responsive but not too radical.

D 68. Install the second nylon tie wrap around the

a l u m i n u m channel and the pushrods right in front of

the tail surfaces. This will help keep the control

surfaces from fluttering.

BALANCING

D 69. With the wing rubber banded to the fuselage, the

fuel tank empty, and everything else in its place, lift the

model by placing one finger tip on the bottom of each

wing at the approximate location of each end of the wing

joiner which is 3" back from the leading edge. The

STURDY BIRDY should hang just slightly nose down

or level. If the plane hangs with the nose pointing up

then you will need to add some weight to the nose of the

plane. There are several ways you can add this weight

including stuffing lead weight around the fuel tank or

using one of the heavy prop nuts available. Under no

circumstance should you try to fly the plane if it does

not balance correctly!

GETTING READY FOR FLYING

D 70. Use at least four rubber bands to hold the

engine/firewall in place and use eight #64 rubber bands

to hold the wing in place.

D 71. We recommend that you use a nylon propeller for

your first flights since it will not break as easily as wood.

Sand the edges of the prop before you use it. The edges

of nylon props are very sharp and should be dulled

before use. If a prop is damaged in any way it should be

discarded and a new prop used in its place.

D 72. Be sure to conduct a range test on your radio

system before every flying session. The instruction

manual that came with your radio should explain how

to properly do this.

D 73. If you are using a new engine in your plane, break

it in on the ground according to the manufacturer's

instructions before attempting to fly the plane.

D 74. Never try to start the engine by flipping it over

with your finger. Always use either an electric starter or

a "Chicken Stick".

D 75. Always adjust the needle valve on the engine from

the back of the plane. Never reach over a rotating

prop! Treat these engines with the utmost respect, they

are not toys!

D 76. After each flight, check the propeller, engine bolts,

control surfaces, control linkages, hinges and rubber

bands for damage or looseness and correct if necessary.

An ounce of prevention here will keep you happily

flying longer.

FLYING

The STURDY BIRDY is a very stable flying

airplane with a unique self-recovering system designed

into it. This makes it one of the easiest-flying planes

available. However, it is highly recommended that you

consult an experienced pilot to help trim out the plane

and help you with your first flights. The most

important thing to remember when learning to fly is

that you need to be able to relate to the control inputs

as if you were sitting in the plane. If you don't, it will

seem like the rudder is working backwards when the

plane is flying towards you. It may also seem a little

strange that you pull the stick down (back) in order to

make the plane go up, but this is how it works in real

planes. It is a good idea to keep facing the same

direction that the model is flying.

16