D 54. Assemble the short throttle pushrod by screwing

the remaining 1" long threaded rod and nylon clevis into

one end of the 12" long inner pushrod and snapping this

assembly onto the throttle servo horn.

D 57. Tack glue or hold these in place for the next step.

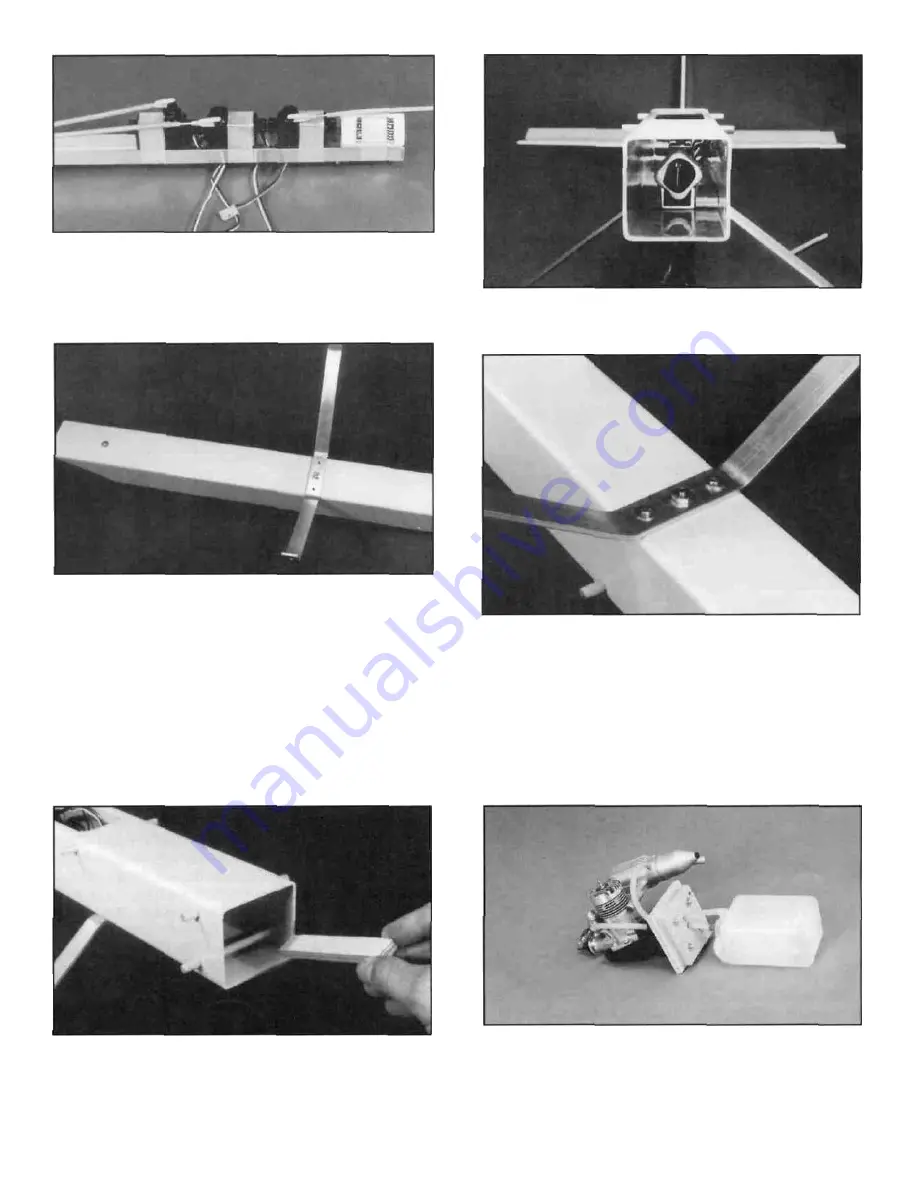

D 55. Attach the plastic fuselage tube to the channel by

sliding it over the channel assembly and pushing the

front 8-32 screw through the middle hole in the bottom

of the tube. Put the aluminum landing gear in place on

the 9-32 screw and secure the whole assembly with a #8

lock washer and an 8-32 hex nut. Insert the remaining 8-

32 screw in the rear hole from the bottom and secure it

with a #8 lock washer and an 8-32 hex nut in the

channel. It is a good idea to use some medium strength

thread locking cement on these bolts.

D 58. Drill a 1/8" diameter hole in each support using

the attached landing gear as a guide. Remove the

supports from the fuselage and enlarge the holes to

5/32". Insert a 4-40 blind nut in each hole and use a

hammer to seat the blind nut in place. Replace the

supports into the fuselage with the blind nut facing

up and use the 4-40 x 5/8" machine screws to hold

everything together.

D 56. Slide the two 1/4" plywood landing gear supports

into the fuselage, one on each side of the aluminum

channel. The front of the supports should be even with

the front of the aluminum channel.

D 59. Assemble your fuel tank according to the

manufacturer's instructions. Connect the fuel tank to

the engine by threading the fuel tubing through the

two holes in the middle of the engine mount and

attaching the pickup line to the carburetor and the

14