Securing the aileron pushrods Install the wing mounting dowels

D 20. Locate the 1/4" (6.5mm) diameter clear

retaining tube and cut two 1/4" (6.5mm) pieces. Slide

one piece onto each clevis to secure the connection

between the clevis and the horn.

This concludes the wing assembly for now. Tape the

pushrods to the wing to keep them in place until you

install the servo.

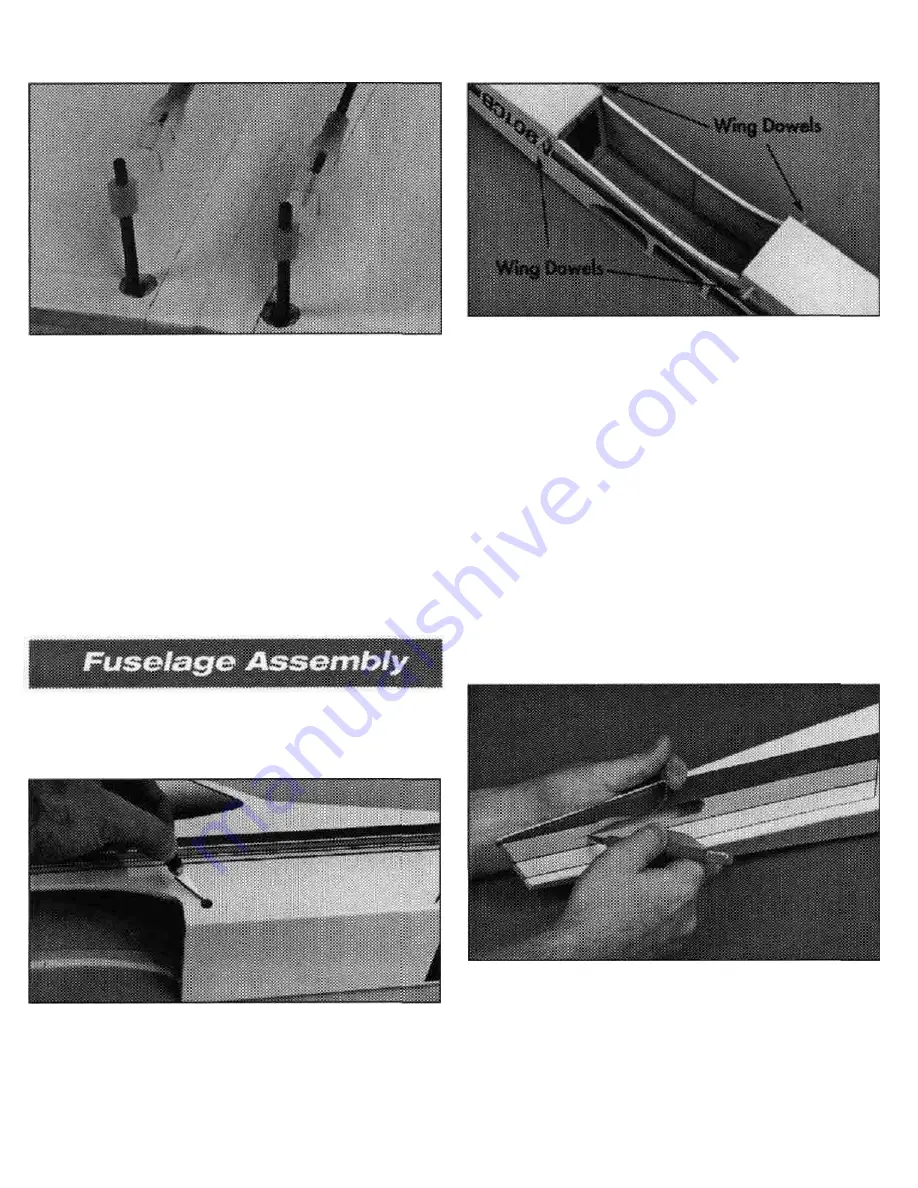

D 2. Insert both wing mounting dowels so they

protrude an equal distance on both sides. Mix 1/4oz.

(7.4ml) of 30-minute epoxy. Apply glue around the

dowels next to the fuselage and slide them in and out

to help force the glue into the holes. Using a paper

towel, spread the excess glue around the ends of the

dowels. This will fuelproof and add strength to the

wood. From the inside of the fuselage, apply more

epoxy around the dowels where they meet the sides of

the fuselage. These wing dowels will be used as anchors

for rubber bands to hold the wing in place. Wipe off all

excess epoxy with a paper towel and rubbing alcohol.

Locate the wing dowel holes

D 1. Locate the four round holes (two on each side of

the fuselage, see photo below for reference) and

remove the covering over each hole.

Caution: Do not cut out the rectangular holes in the

side of the fuselage.

Locate the stabilizer slot

D 3. Locate the horizontal stabilizer slot under the

covering on the tail section of the fuselage by pressing

lightly with your finger. The slot is located on both

sides of the tail. Using a hobby knife, carefully remove

the covering, exposing the slots.

NOTE: Do not cut into the wood around the slot.

10