7

clothespins to clamp the wing joiners together firmly. The

excess epoxy

must

be removed before it dries-see Step

#

5.

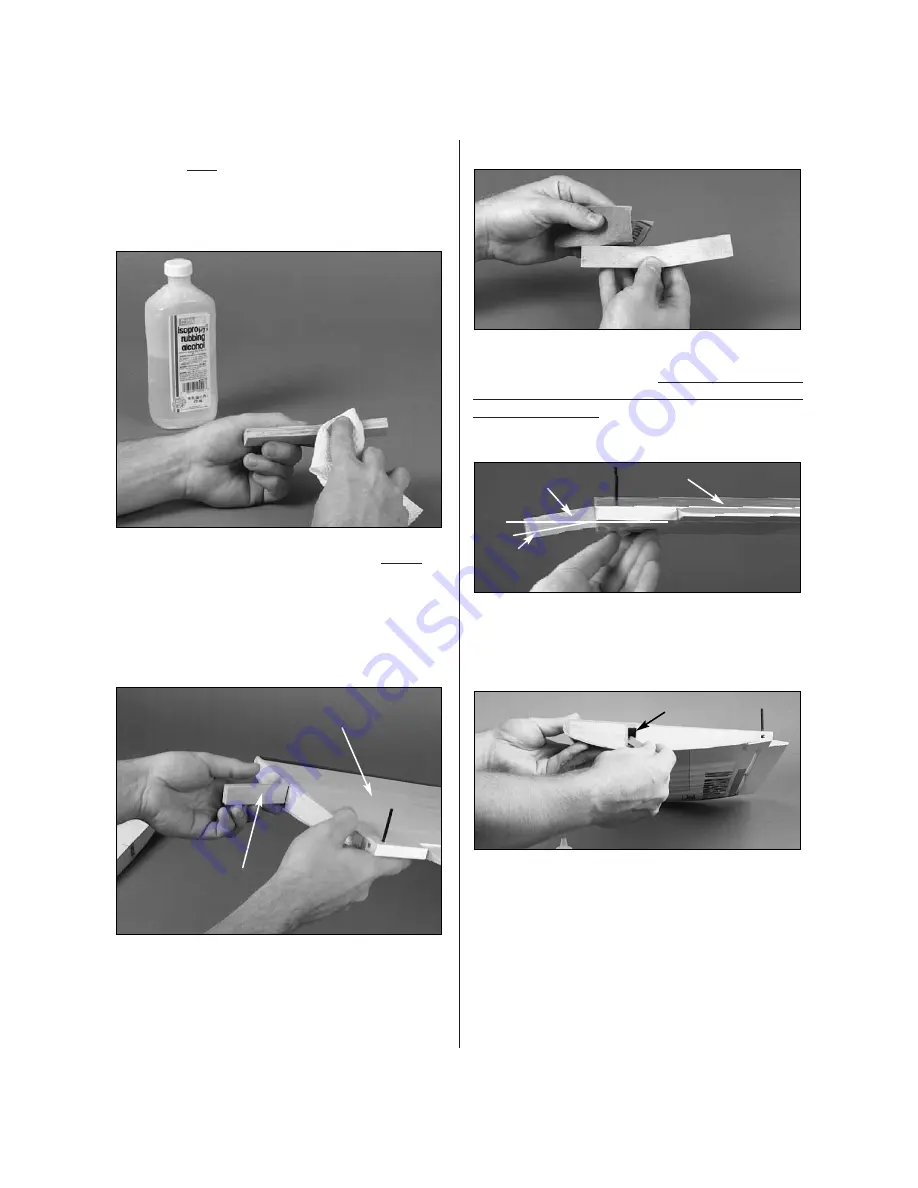

Removing the excess epoxy

❑

5. Excess epoxy will be squeezed out of the seams

between the joiners and must be removed

before

the

epoxy is allowed to cure. Use a paper towel and

rubbing alcohol to remove the excess epoxy. Be careful

not to disturb the alignment of the joiner pieces.

Test fit the wing joiner

❑

6. A f t e r t h e e p o x y h a s c u r e d a n d t h e

clothespins have been removed, test fit the wing

joiner in both wings by sliding the joiner into

the joiner cavity in the wing. The joiner should

s l i d e i n w i t h a l i t t l e r e s i s t a n c e u p t o t h e

centerline drawn on the both sides of the joiner.

Sanding the joiner

❑

7. If the wing joiner will not fit in the cavity, lightly

sand the excess epoxy and uneven surface joints from

the joiner edges and sides.

Caution:

A snug fit is

desirable between the joiner and the wing cavity. Do

not sand excessively.

Viewing the wing dihedral

❑

8. Pay close attention to the orientation of the wing

joiner in relation to the dihedral of the wings as shown.

Gluing the joiner in the wing

❑

9. Mix 1/4oz. (7.5ml) of 30-minute epoxy to glue

the joiner into one wing half. Use a mixing stick or

epoxy brush to apply epoxy to all four sides of the

joiner cavity wall. Insert the joiner into the cavity up

to the centerline marked on the joiner plate. Be sure

you are installing the joiner in the correct orientation

to the wing. Clean the excess epoxy from the wing

root rib. You must be sure all the excess glue is

removed from the wing root or the wings will not fit

together correctly. Allow enough time for the epoxy to

fully cure before proceeding to the next step.

7

Bottom of wing

Wing joiner

Bottom of wing

Note the direction

of the joiner

Wing joiner cavity

Dihedral angle

Summary of Contents for Awarf Series

Page 1: ...Easy as 1 2 3 V1 3 Copyright 1998 ...

Page 40: ......