Installing the switch

Q Cut a rectangular switch hole in the side of the

fuselage opposite the exhaust using a hobby knife.

Locate the receiver switch harness in the radio

system and remove the face plate. Place the switch

into the hole with the switch facing outward. Put

the face plate over the switch and mark the screw

holes with a felt-tip marker using the plate as a

template. Drill the screw mounting holes using a

1/16" (1.5mm) drill bit. Install the switch from the

inside of the fuselage with the "on" position toward

the rear of the plane. If the switch should get hit

while the plane is moving forward, it would not

turn the receiver off. Secure the switch using the

two screws supplied with the switch.

Preparing the servos

Q Remove the servo arms and wheels from the three

servos. Install the rubber grommets that came with

the radio system onto the servos, following the

instructions included with your radio system.

Servo installation

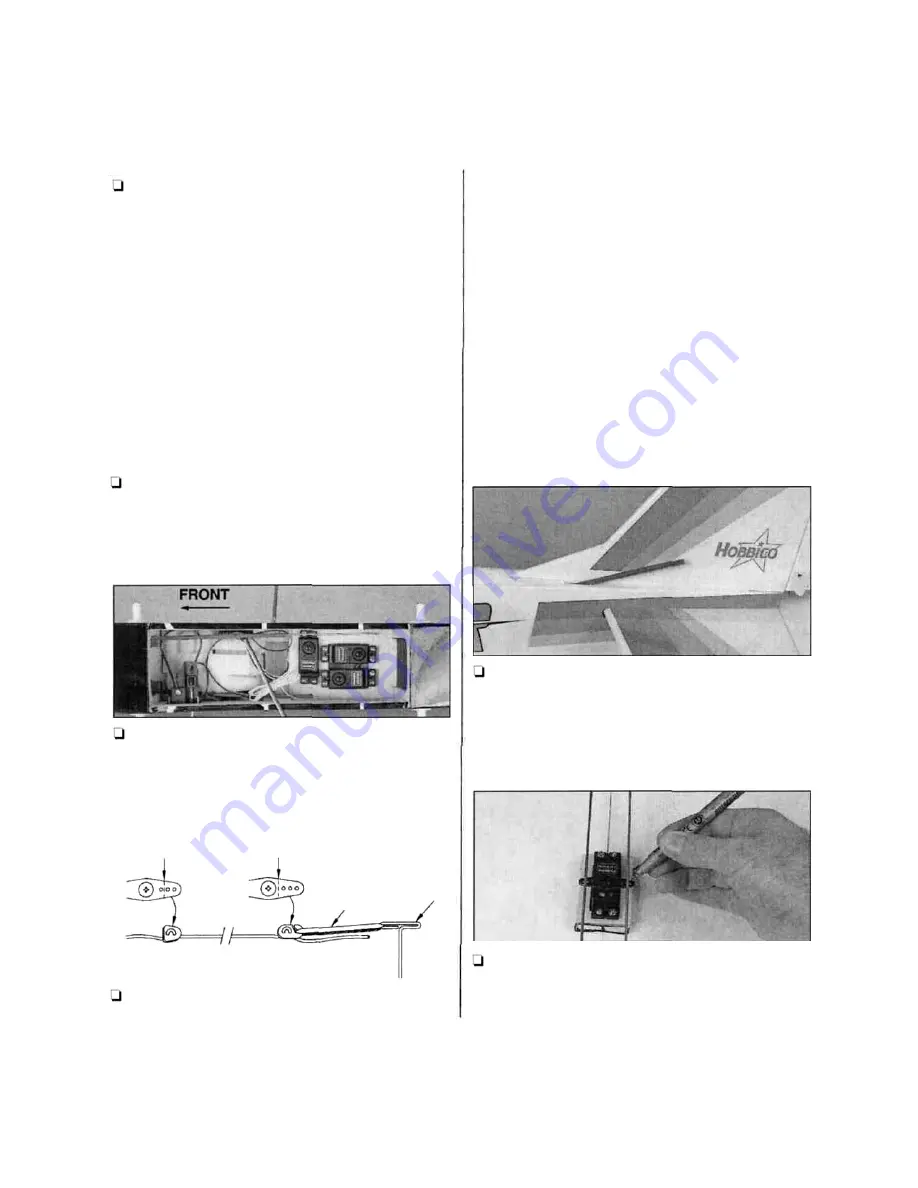

1-1 Install the three servos from your radio system as

shown in the photo. Refer to the radio manufacturer's

manual for more detailed instructions. Notice the

location and orientation of each servo as well as the

switch location.

Antenna Routing

STRAIN RELIEF

INSIDE FUSELAGE

ANTENNA HOLDER

AT THE TOP OF THE

VERTICAL STABILIZER

CUT

CUT

RUBBER

BAND

Q Drill a 1/16" (1.5mm) exit hole in the center of the

rear window 1" (25.4mm) down from the edge of the

radio compartment. Route the antenna under the

plywood servo tray and up through the exit hole. Do

not cut the antenna wire. The receiver is tuned to a

specific length of antenna. Use a medium T-pin to

attach a rubber band to the top portion of the

vertical stabilizer. Tie the antenna to the rubber

band using tension to keep the antenna tight. Use

caution not to damage the antenna. A servo horn

can be cut and used to hold the antenna in place at

both ends with less likelihood of damage to the

antenna wire.

Q Locate the two 21-3/4" (555mm) outer pushrod

tubes. Slide the tubes into the fuselage from the

elevator and rudder pushrod exits. Enlarge the

exits to allow the tubes to slide in easily. Don't glue

the tubes at this time.

Q Center the ailerons, then mark the pushrods at

the point where they meet the holes in the servo

arm. Make a 90 degree bend down in the wires at

this mark.

T-PIN

17