--- 20 ---

Replace the piston bumper.

Reassemble or replace.

Repair or replace.

Remove the dirt and apply

oil, or replace.

Replace the defective part.

Apply grease.

Replace the head valve

spring.

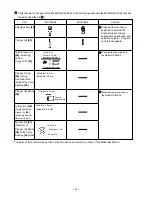

<Output section>

Air pressure is too low.

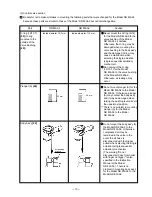

Problem

Possible cause

Inspection method

Remedy

Check if the nails can be

driven at 5 kgf/cm

2

.

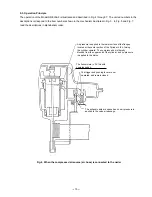

After making idle driving,

check if the driver blade is

kept in the down position.

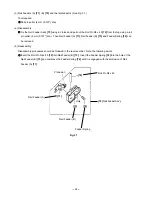

Disassemble the control

valve and check the O-ring.

Adjust for 5 to 8.5 kgf/cm

2

.

Replace the piston ring.

Piston O-ring is worn or

damaged.

Piston bumper is abnormal

(dislocated, deformed or

damaged).

Cylinder ring is abnormal

(dislocated, deformed or

damaged).

Driver blade is abnormal

(deformed, burrs, damaged

or fatigued).

Cylinder's internal surface is

abnormal (deposits of dirt or

worn).

<

Control valve section >

Plunger (A), Plunger (B) or

valve bushing is abnormal

(galled or damaged).

O-ring is worn or oiling is

needed.

Replace the defective part.

Apply grease or replace.

Nails are not fully fed into

the injection port.

Unspecified nails are used.

Driver blade is worn.

Workpiece is very hard.

2) Nails are bent

when being

driven.

See item 1).

Check if the driver blade tip

is abnormally worn.

Drive a nail into soft wood

workpiece and check if the

nail is bent.

See item 1).

Replace the driver blade.

Do not use unspecified

workpieces.

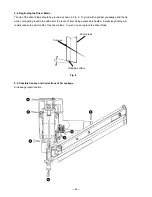

Set the single actuation/

contact actuation selector to

the contact actuation.

Pull the nail feeder

backward to perform idle

driving. Check if the driver

blade has returned.

Summary of Contents for NR 83AA3

Page 45: ......