-19-

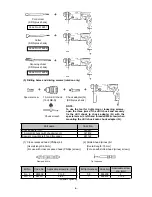

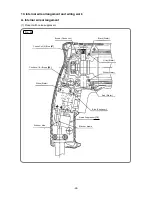

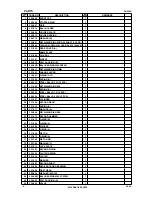

Lock Plate

[39]

Second Pinion

[40]

Washer

[43]

Clutch

[42]

Clutch Spring

[41]

Lock plate assembly

Grip

[3]

Front Cap

[1]

Grip

[3]

Holder Spring

[6]

Steel Ball D7.0

[23]

Cylinder

[25]

Washer (B)

[7]

Holder Plate

[5]

Stopper Ring

[2]

Ball Holder

[4]

Fig. 15

Fig. 13

Fig. 14

Be sure to disconnect the power cord plug from the wall outlet before conducting repair. Otherwise, the

motor may suddenly run, posing a very dangerous situation.

1. Precautions on Disassembly and Reassembly

The

[Bold]

numbers in the descriptions below correspond to item numbers in the Parts List and exploded

view assembly diagram for the Model DH 22PH.

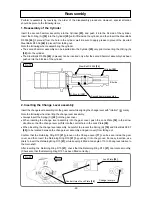

1. Disassembly of the tool retainer

While fully pulling the Grip

[3]

in the arrow direction, remove the Front Cap

[1]

. While pulling the Grip

[3]

in

the arrow direction, use a stopper ring removal tool to remove the Stopper Ring

[2].

Now you can remove

the Grip

[3]

, Ball Holder

[4]

, Steel Ball D7.0

[23]

, Holder Plate

[5]

, Holder Spring

[6]

and Washer (B)

[7]

from the Cylinder

[25]

.

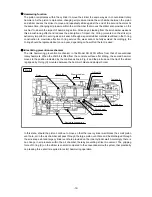

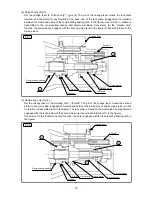

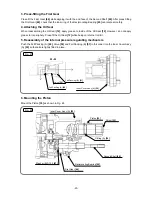

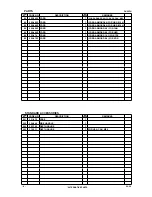

2. Disassembly of the hammering mechanism

Set the Change Lever

[17]

to "rotation and hammering" ( marks), remove the Tapping Screws

(W/Flange) D4 x 30 (black)

[9]

from the Gear Cover (A)

[10]

, and then remove the Gear Cover (A)

[10]

.

Leave the lock plate assembly mounted in the removed Gear Cover (A)

[10]

.

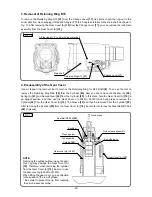

Turn the Second Shaft

[44]

until the Piston

[35]

moves to the top dead center (on the Inner Cover Ass’y (A)

[52]

side). The arm of the Reciprocating Bearing

[45]

can be removed from the Piston Pin

[37]

, and parts

fitted onto the Second Shaft

[44]

can be removed together from the Inner Cover Ass’y (A)

[52]

.

Use a bearing removal tool to remove the First Gear

[46]

from the Second Shaft

[44]

, and then remove the

Reciprocating Bearing

[45]

from the Second Shaft

[44]

.

Note carefully that the First Gear

[46]

is positioned for press-fitting with reference to the 9-mm-diameter

end face of the Second Shaft

[44]

.

Disassembly

REPAIR GUIDE