-12-

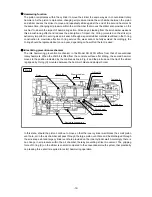

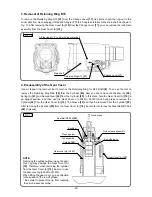

Fig. 4

Hammering function

The piston reciprocates within the cylinder to move the striker the same way as in conventional rotary

hammers. As the piston reciprocates, changing air pressure inside the air chamber between the piston

and striker causes the striker to move and repeatedly strike against the end of the second hammer. At

the same time, changing air pressure within the air chamber that moves the striker also provides an "air

cushion" to absorb the impact of hammering action. Since any air leaking from the air chamber weakens

this air-cushioning effect and reduces the absorption of impact, the O-ring (mounted on the striker) is

extremely important in serving as an air seal. Although a special rubber material is utilized in the O-ring

construction to maximize effective O-ring service life, wear cannot be fully avoided. Accordingly, the

O-ring should be replaced about once a year, depending on how often the tool is used.

Idle striking prevention mechanism

The idle hammering prevention mechanism in the Model DH 22PH differs from that of conventional

rotary hammers. When the drill bit is lifted from the concrete surface after drilling, the second hammer

moves to the position indicated by the continuous line in Fig. 4 and the protrusion at the tip of the striker

is gripped by O-ring (C) mounted between the hammer holder and damper holder.

In this state, should the piston continue to move so that the inner cylinder wall blocks the small piston

vent hole, air in the air chamber will pass through the large piston vent hole and be discharged through

the air-escape slot and large cylinder vent hole provided on the inner cylinder wall. Accordingly, there is

no change in air pressure within the air chamber, thereby preventing striker movement. The gripping

force of O-ring (C) on the striker is so small compared to the conventional mouth system, that practically

no pressing force at all is required to restart hammering operation.

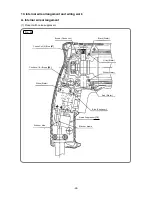

Tool shaft

Cylinder

Reciprocating bearing

Cylinder flange

Second gear

Coil spring

Striker

Spring (A)

Piston

Slip mechanism

O-Ring (C)

Clutch