-15-

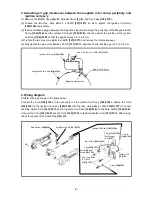

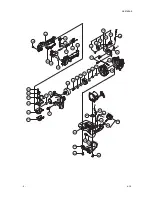

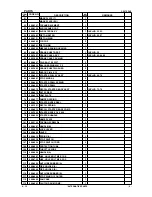

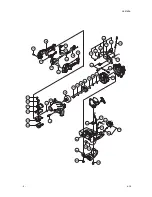

5. Reassembling the gear case section

(1) Reassembling the gear case section

First, press-fit the Ball Bearing 627 C3

[199]<199>

into the Case

[220]<220>

.

NOTE: Be careful not to tilt the Ball Bearing 627 C3 [199]<199>.

Confirm that the Screw 6 x 8

[189]<189>

is tightened. Apply seven to nine grams of specified Cosmo

Molybdenum No. 2 grease to the Ball Bearing 627 C3

[199]<199>

in the Case

[220]<220>

. Set the

Cam

[200]<200>

on the Ball Bearing 627 C3

[199]<199>

, and then press-fit the Gear

[201]<201>

(to

which the Ball Bearing 638Z

[202]<202>

is press-fitted) into the Ball Bearing 627 C3

[199]<199>

in the

Case

[220]<220>

. Next, assemble the Stop Ring C-28, Inner

[203]<203>

. Press-fit the Ball Bearing

609

[193]<193>

and the Ball Bearing 609Z ST

[194]<194>

to the Pinion

[192]<192>

, and then attach

the Stop Ring C-9, Outer

[195]<195>

. Apply 0.1 to 0.3 grams of specified Cosmo Molybdenum No. 2

grease to the gear section of the Pinion

[192]<192>

. Then press-fit the pinion ass’y to the Case

[220]<220>

and assemble the Stop Ring C-24, Inner

[196]<196>

.

NOTE: Confirm that the Pinion [192]<192> rotates smoothly when turning the Gear [201]<201>.

Insert the Collar

[204]<204>

and the Sprocket Comp., 3/8

[205]<205>

into the shaft of the Gear

[201]<201>

, and then use a spanner to tighten the Flange Nut 6

[206]<206>

with both 32 mm wide

sides of the Sprocket Comp., 3/8

[205]<205>

fixed in place.

NOTE: Confirm that the Sprocket Comp., 3/8 [205]<205> rotates under the following operating

load.

Operating load: 1.18 N to 1.76 N (120 gf to 180 gf)

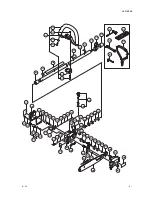

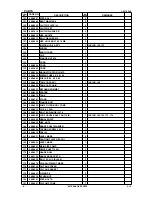

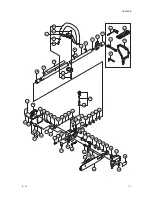

(2) Reassembling the oil tank section

Apply Turbine Oil 56 (JX Nippon Oil & Energy) to the inner and outer peripheries of the O-ring

[182]<182>

, and then attach the O-ring

[182]<182>

to the Oil Pump Comp.

[181]<181>

.

Apply Primary Oil SAE30 (JX Nippon Oil & Energy) to the shaft of the Oil Pump Piston Comp.

[186]<186>

, and Turbine Oil 56 (JX Nippon Oil & Energy) to the inner and outer peripheries of the

O-ring 1.4

[183]<183>

. Pass the Oil Pump Spring

[185]<185>

and the Washer 2

[184]<184>

through

the Oil Pump Piston Comp.

[186]<186>

, and then insert it into the Oil Pump Comp.

[181]<181>

.

NOTE: Confirm that the Oil Pump Piston Comp. [186]<186> operates.

Insert the assembled Oil Pump Comp.

[181]<181>

into the side hole of the Case

[220]<220>

as

passed from the oil tank to the gear chamber with the Oil Pump Piston Comp.

[186]<186>

side facing

up. Pass the Step Bolt A

[180]<180>

through the ring section of the Oil Tank Cap Ass’y

[188]<188>

and tighten the Step Bolt A

[180]<180>

to temporarily secure the Oil Pump Piston Comp.

[186]<186>

in place. Insert the Oil Pump Adjuster

[217]<217>

with the O-ring P-5

[178]<178>

from the front hole of

the Case

[220]<220>

and then tighten the adjuster so that its male screw engages with the Oil Pump

Comp.

[181]<181>

until the attachment groove for the Stop Ring E-6

[218]<218>

of the Oil Pump

Adjuster

[217]<217>

protrudes from the inner side of the oil tank of the Case

[220]<220>

. Once the

attachment groove protrudes out, attach the Stop Ring E-6

[218]<218>

to the groove.

NOTE: Before attaching the O-ring P-5 [178]<178>, apply Turbine Oil 56 (JX Nippon Oil &

Energy) to its inner periphery.

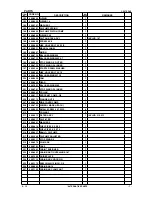

Insert the Fuel Pipe 3 x 5 x 75

[215]<215>

to the end of the Banjo, Oil Pump

[216]<216>

.

NOTE: At that time, do not apply ethanol, oil, or other treatment to the inner periphery of the

Fuel Pipe 3 x 5 x 75 [215]<215> and the Banjo, Oil Pump [216]<216>.