-14-

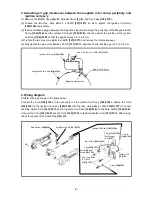

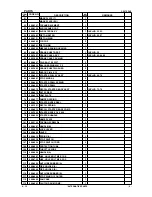

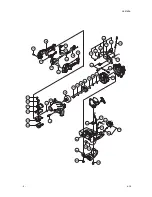

4. Disassembling the gear case section

(1) Slightly loosen the Chain Bar Clamp Nut

[227]<227>

while being careful not to remove it.

Turn the Oil Pump Adjuster

[217]<217>

counterclockwise to decrease the tension of the Saw Chain

[225]<225>

.

NOTE: Turning the Oil Pump Adjuster [217]<217> counterclockwise decreases the tension of

the Saw Chain [225]<225>; turning it clockwise increases the tension.

(2) Remove the Chain Bar Clamp Nut

[227]<227>

and the Side Cover Comp.

[207]<207>

, and then

remove the Chain Bar 10

[226]<226>

and the Saw Chain

[225]<225>

.

Loosen the Hex. Hole Bolt 5 x 22/S

[190]<190>

and the Hex. Hole Bolt 5 x 10

[198]<198>

, and then

remove the gear case ass’y from the Main Pipe Comp.

[170]<170>

.

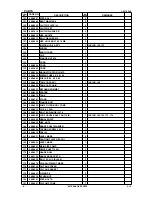

(3) Open the Oil Tank Cap Ass’y

[188]<188>

and then drain out the chain oil from the oil tank.

Remove the four Small Screws 4 x 12WS

[209]<209>

, and then remove the four Collars 3

[210]<210>

,

Oil Tank Cover

[176]<176>

, and Oil Tank Gasket

[177]<177>

.

Remove Stop Ring E-6

[218]<218>

and turn the Oil Pump Adjuster

[217]<217>

(with O-ring P-5

[178]<178>

) counterclockwise to remove the adjuster.

Turn the Step Bolt A

[180]<180>

(with the O-ring P-5

[178]<178>

and the 8 Push Nut

[179]<179>

)

counterclockwise to remove the Step Bolt A

[180]<180>

.

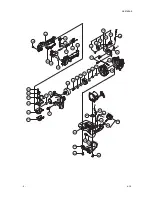

(4) Remove the Oil Pump Comp.

[181]<181>

together with the Filter Ass’y

[211]<211>

, Fuel Pipe 3 x 5 x

60

[214]<214>

, Fuel Pipe 3 x 5 x 75

[215]<215>

, O-ring

[182]<182>

, O-ring 1.4

[183]<183>

, Washer

2

[184]<184>

, Oil Pump Spring

[185]<185>

, and Oil Pump Piston Comp.

[186]<186>

.

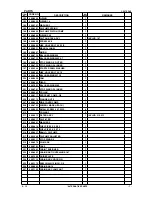

(5) Remove the Stop Ring C-24, Inner

[196]<196>

to remove the Pinion

[192]<192>

, Ball Bearing 609

[193]<193>

, Ball Bearing 609Z ST

[194]<194>

, and Stop Ring C-9, Outer

[195]<195>

; however, as

these parts cannot be removed by hand, heat the Case

[220]<220>

and then strike with a rubber

hammer in order to pull out the Pinion

[192]<192>

, Ball Bearing 609

[193]<193>

, Ball Bearing 609Z

ST

[194]<194>

, and Stop Ring C-9, Outer

[195]<195>

as a complete set.

NOTE: Be sure to wear thick cotton gloves or similar protection when holding the heated Case

[220]<220>, so as to avoid burning your hands. Also be careful not to deform the Case

[220]<220>.

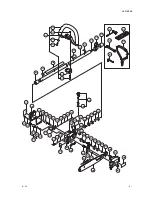

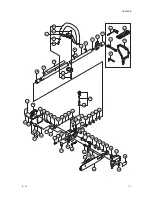

(6) Use a spanner to remove the Flange Nut 6

[206]<206>

with both 32 mm wide sides of the Sprocket

Comp., 3/8

[205]<205>

fixed in place, and then remove the Flange Nut 6

[206]<206>

, Sprocket Comp.,

3/8

[205]<205>

, and Collar

[204]<204>

in this order. Remove the Stop Ring C-28, Inner

[203]<203>

to

remove the Ball Bearing 638Z

[202]<202>

, Gear

[201]<201>

, Cam

[200]<200>

, and Ball Bearing 627

C3

[199]<199>

; however, as the Gear

[201]<201>

cannot be pulled out by hand, heat the Case

[220]<220>

and then strike it with a rubber hammer in order to pull out the Ball Bearing 627 C3

[199]<199>

, the Cam

[200]<200>

, Gear

[201]<201>

, and Ball Bearing 638Z

[202]<202>

as a

complete set.

NOTE: Be sure to wear thick cotton gloves or similar protection when holding the heated Case

[220]<220>, so as to avoid burning your hands. Also be careful not to deform the Case

[220]<220>.

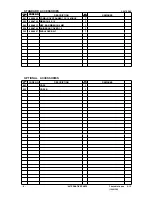

(7) Note that the Chain Bar Tightening Bolt

[222]<222>

cannot be removed; therefore, replace it together

with the Case

[220]<220>

if the Chain Bar Tightening Bolt

[222]<222>

breaks or becomes unusable.

Before removing the Pinion

[192]<192>

, use a hand press or similar tool to remove the Stop Ring C-9,

Outer

[195]<195>

, Ball Bearing 609

[193]<193>

, and Ball Bearing 609Z ST

[194]<194>

in this order.

Likewise, before removing the Gear

[201]<201>

, use a hand press or similar tool to remove the Ball

Bearing 627 C3

[199]<199>

and the Ball Bearing 638Z

[202]<202>

.

NOTE: When pulling out the Ball Bearing 627 C3 [199]<199>, be careful not to damage the Cam

[200]<200>.