18

3.1 Voltage Measurement

Quick Start Manual

To set an arbitrary recording period, choose "

OFF

" for "

Continuous

"

and then set the desired time.

Unless the Store CH setting is on, it is not possible to make input

settings in the channel screen.

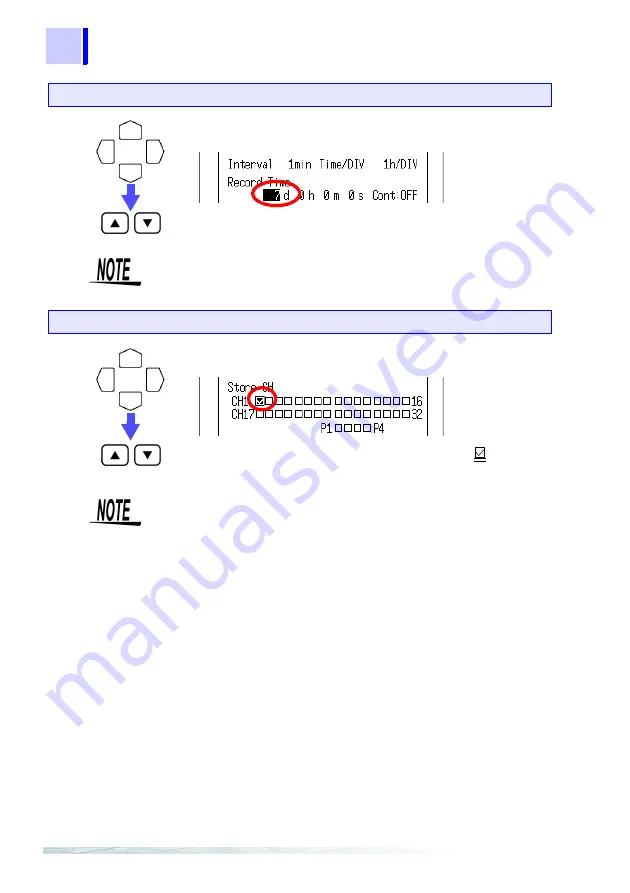

Set the recording period (Record Time) to "7 days."

Move the blinking cursor to the position shown.

Select "

7 d

."

Turn on the channel 1 (CH1) of the Store CH.

Move the blinking cursor to the position shown.

Turn on the channel 1, by putting a check mark in the CH1

box of Store CH.

Summary of Contents for 8420-51

Page 1: ...MEMORY HiLOGGER QUICK START MANUAL 8420 51 8421 51 8422 51 ...

Page 2: ......

Page 4: ...ii Quick Start Manual Contents ...

Page 7: ...3 1 2 3 4 5 6 7 8 9 10 11 Identification of Controls and Indicators 1 ...

Page 12: ...8 1 1 Identification of Controls and Indicators Quick Start Manual ...

Page 16: ...12 2 3 Waveform Screen Quick Start Manual ...

Page 50: ...46 3 3 Integrating the Pulse Output from a Power Meter Quick Start Manual ...