14 Plow Assembly

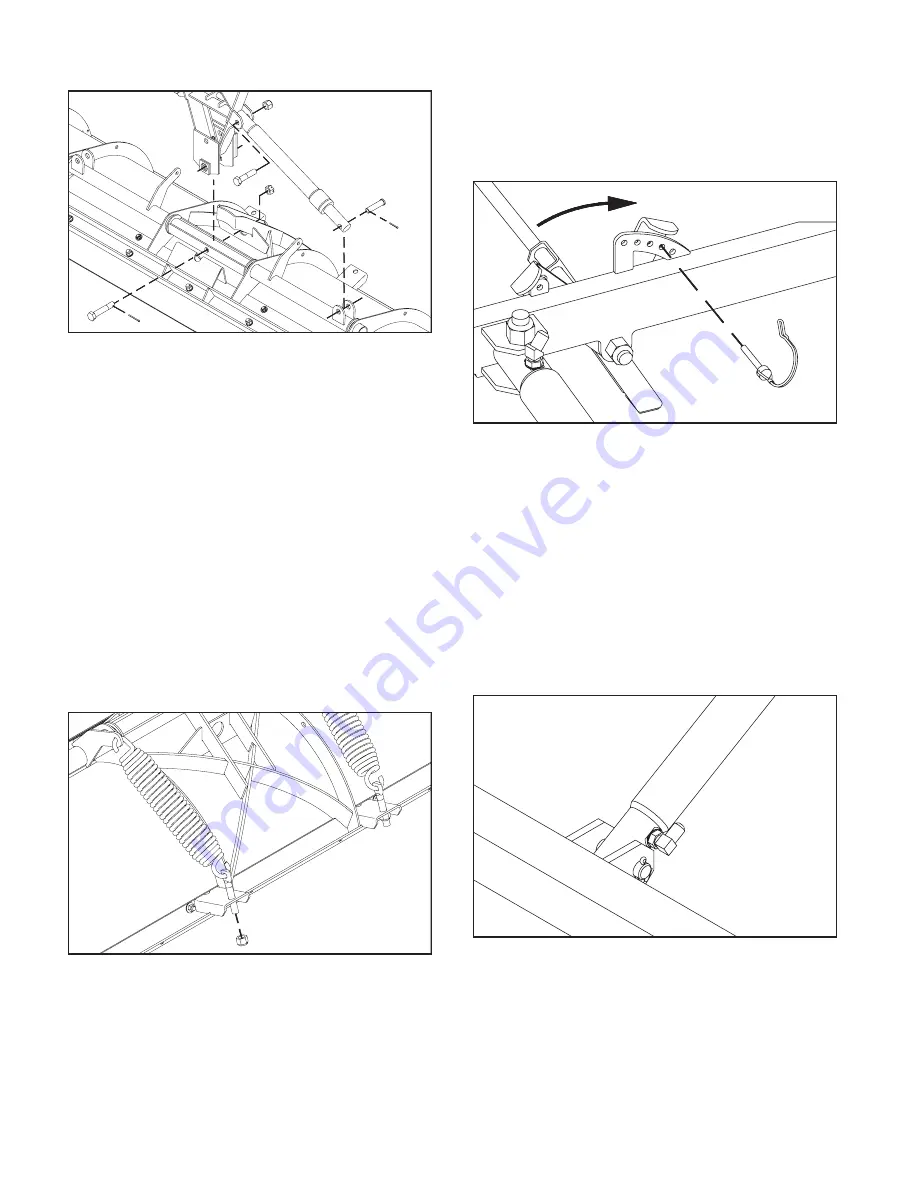

3. Gently tip the plow assembly to its working

position with a hoist or forklift. Pin the park-

ing stand to hold the push frame parallel to

the ground.

DWG NO. 5696

Swing the lift frame up to its approximate

working position and hold with a hoist or

forklift for installation of the lift cylinder.

The bottom surface inside the two prong re-

ceiver channels should measure about 10

inches above the ground in the working po-

sition.

4. Locate the 90

O

O-ring/flare adapter in the

hardware bag from the parts box.

DWG NO. 5699

Install the O-ring end of the 90

O

fitting into the

lift cylinder port so that the flared end points

toward the rod end when tightened.

Pin the lower end of the lift cylinder between

the lugs on the frame assembly with the hard-

ware provided. The 90

O

adapter should be on

the RH side of the cylinder.

DWG NO. 5698A

Install the 3/4 inch x 4 1/4 inch hex bolt re-

moved earlier so the bolt head is retained

by the lock plate on the push frame. Secure

the assembly with the 3/4 inch slotted nut

and cotter pin so the plow blade is free to

pivot.

Use clevis pins and cotter pins to fasten the

hydraulic cylinder rods between lugs on the

moldboard. Cylinder ports should be direct-

ed up.

2. From the parts box, remove two extension

springs.

Inside the hardware bag, find two threaded

spring studs and two 5/8 inch nylon insert

lock nuts.

DWG NO. 5692A

Slide a spring stud onto each spring, then

assemble springs between lugs on the

moldboard pivot tube and channels along

the upper edge of the blade.

Tighten lock nuts until spring coils begin to

separate.