Service 31

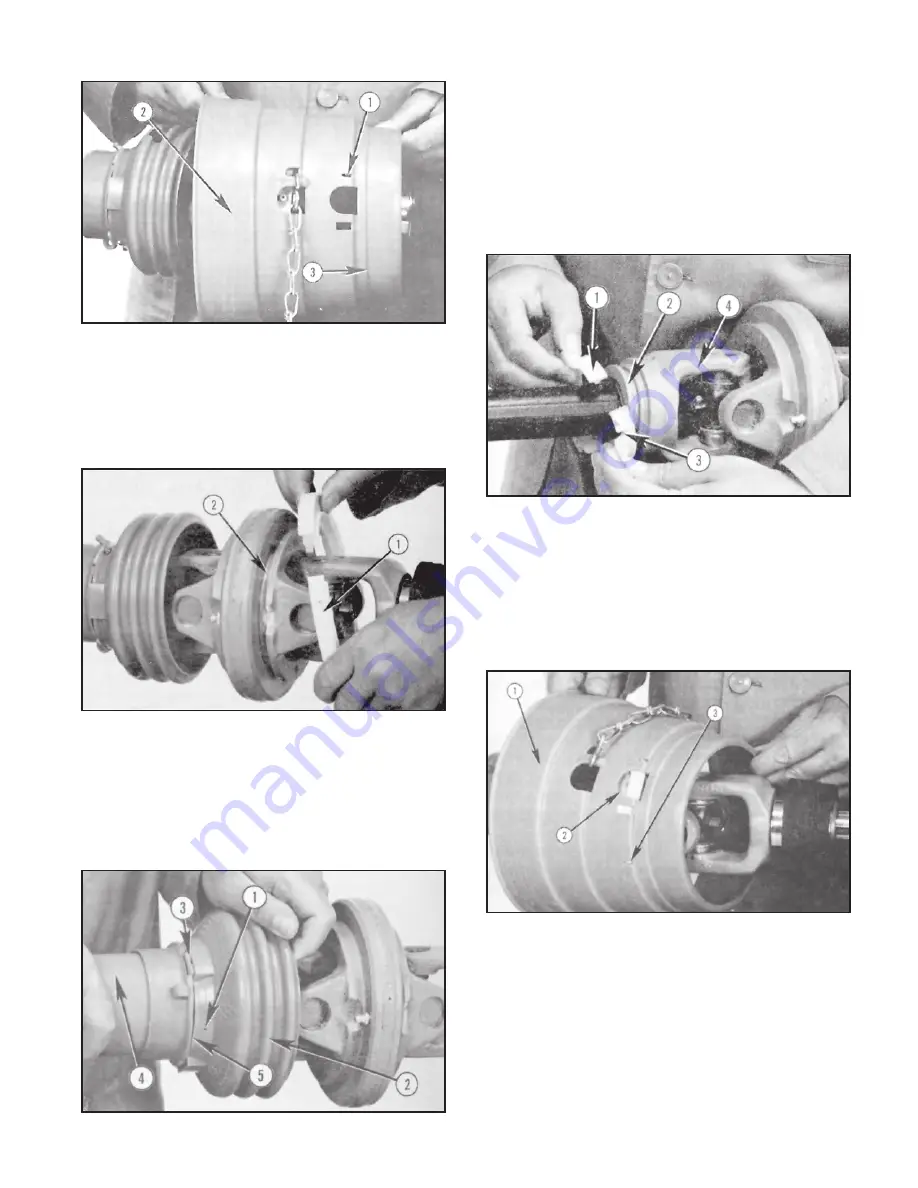

FIGURE 64 PHOTO NO. 3036

2. Remove, clean and inspect large bearing ring

Item 1 in Photo 3037. Replace if worn or dam-

aged. Clean ring track Item 2 and thoroughly

relube it, as well as bearing ring, before reas-

sembly.

FIGURE 65 PHOTO NO. 3037

3. Remove Phillips locking screw Item 1 in Photo

3038 and rotate shield cone Item 2 to disassem-

bly position Item 3. Snap cone and tube shield

free of small plastic bearing ring. Shield cone

Item 2 and tube shield Item 4 can be pryed apart

with a flat screwdriver applied along area Item 5.

FIGURE 66 PHOTO NO. 3038

4. Remove, clean and inspect small bearing ring

Item 1 in Photo 3039. Replace if worn or dam-

aged. Clean ring track Item 2 and thoroughly

relube it, as well as bearing ring, before reas-

sembly. When reinstalling bearing ring, insure

recesses and tabs Item 3 are AWAY from “U”

joint Item 4. Reinstall shield cone in original

locked position and reinsert Phillips screw.

FIGURE 67 PHOTO NO. 3039

5. Reinstall double yoke cone Item 1 in Photo

3040 over large bearing ring. Insure zerk is

aligned with cone cut out Item 2. Check that 6

holes for previously removed Phillips screws

are aligned with recesses Item 3 provided and

reinstall screws.

FIGURE 68 PHOTO NO. 3040

Summary of Contents for 5710

Page 2: ......

Page 50: ...NOTES 48 Notes ...