10

Before use

The SF 120-A may be used only with the SBP 12

or SFB125 battery.

Before it is used for the first time, it is important

that a new battery is charged for 24 hours in normal

charging mode or up to 12 hours using the condition-

ing charging mode, thus permitting “forming” of the

battery cells to take place.

Battery performance drops at low temperatures. Store

the battery at room temperature when not in use.

Do not store a battery where it may be subjected to high

temperatures, e.g. exposed to the sun, at a window,

behind a car windscreen or on a radiator.

Do not work with the battery until it is run down. The

cells can be damaged if the battery is completely dis-

charged.

Operation

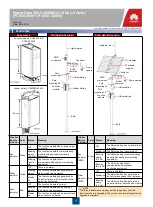

Insert tool insertion and removal

Use the safety catch

as protection against unin-

tentional switching on during transport.

Quick-release chuck

An insert tool can be clamped or released without a chuck

key. When the screwdriver is switched off by the on-off

control switch, the spindle is locked. This is a help when

opening / tightening the quick-release chuck.

Battery removal

Battery release button

If the battery has to be changed, press in the two release

buttons using two fingers and pull the battery out of the

screwdriver.

Battery insertion

Push in the battery as far as it will go. There must be an

audible click.

Only the Hilti SBP12 or SFB125 batteries may be used.

Battery charging

Only the Hilti SFC 7/18, TCU 7/36 or SBC 12 H battery

charger may be used. Please refer to the charger oper-

ating instructions for the charging process.

If the SFB 125 battery is charged in the old SBC 12 H

charger, a loss of capacity must be expected with this

kind of charging. Full capacity of the charger will be

obtained with the SFC7/18 and TCU7/36 chargers.

Speed selection

Two-speed switch

The speed can be selected using the mechanical two-

speed switch, i.e. 1

st

speed: 0–320 r.p.m. or 2

nd

speed:

0–1150 r.p.m. Only change speed when the screwdriv-

er is not running.

Torque selection

Torque clutch setting ring

The release torque (1–10 Nm) is obtained by turning the

setting ring to the desired torque level (setting 1–20).

At the drilling symbol (

), the torque clutch is

blocked and the screwdriver gives its max. torque of

about 21 Nm (stalling torque) at this setting.

Reversing switch

The reversing switch is used to reverse the direction of

rotation of the chuck. A locking device prevents opera-

tion of the switch while the motor is running. The con-

trol switch

is deactivated when the reversing switch

is in the central position.

Speed control

Switch with electronic speed control

The speed can be controlled infinitely from zero to max-

imum by slowly depressing the switch.

Care and maintenance

Care of the tool

The outer casing of the tool is made of impact-resistant

plastic. Sections of the grip are made of an elastomer

material.

Clean the outside of the tool at regular inter-

vals using a slightly damp cloth. Do not use a spray,

steam pressure cleaning equipment or running water

for cleaning. This may negatively affect the electrical

safety of the tool. Always keep the grip surfaces of the

tool free from oil and grease. Do not use cleaning agents

which contain silicone.

Never operate the tool when the ventilation slots

are blocked. Clean the ventilation slots carefully using

a dry brush. Do not permit foreign matter to enter the

interior of the tool.

Take care of your insert tools. Clean off dirt and dust

deposits. Always keep the connection end clean and

lightly greased.

SBP12 and SFB125 batteries

Keep the contact surfaces free of dust and lubricants.

Clean them if necessary using a clean cloth. If the bat-

tery capacity drops below an acceptable level after a long

period of use, we recommend that it be diagnosed by

Hilti.

Printed: 07.07.2013 | Doc-Nr: PUB / 5070589 / 000 / 00