9

9

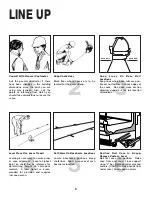

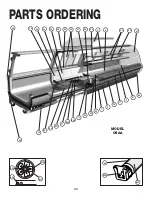

Close joints of front panel. The panel is

slotted on the bottom to allow left or

right adjustment as required.

10

Install curved front panel joint (if cases

come equipped with curved front pan-

els). Curved panel joints are shipped

loose in the case and are attached with

the screws provided. Wide joints (1”)

are for case-to-case joining and narrow

joints (1/2”) are for cases with ends.

11

Attach lower front panel (for cases on

11” baseframes). Slots and tabs are

designed for easy installation without

fasteners. The lower front panel is slot-

ted to allow adjustment left or right as

required.

12

Install top sill joint. The top sill joints are

shipped loose in the case. The front lip

of the joint fits into the crevice between

the top sill and the glass pressure bar.

The rear lip is attached to the back of

the case with the screws provided.

13

Install rear sill joint. The rear sill joints

are shipped loose in the case. The bot-

tom portion of the joint should be slid on

the rear sill first then the top lip fits

between the rear sill and the mullion.

Secure the joint underneath the rear sill

with the screws provided.

14

Install the “J” rail onto the case base

rail. For cases with an 11” baseframe,

the “J” rail easily slides over the base

rail and requires no fasteners. Space

“J” rails evenly along the base rail (2 “J”

rails per 6’, 8’, and 12’ case). For cases

with the 7” baseframe there is a single

“J” rail that is screwed into place.

15

Insert kickplate into “J” rail. Slide the

kickplate up and behind the lower front

panel bracket then down on the “J” rail.

NOTE: An easy technique for one

person is to press against nose

bumper with leg as you guide

bumper into channel with a screen

spline. Insert bottom first.

CURVED FRONT

PANEL JOINT

CURVED FRONT

PANEL

TOP SILL

JOINT

TOP SILL

GLASS

PRESSURE

BAR

REAR SILL

JOINT

REAR SILL

MULLION

16

Insert nose bumper into master bumper

channel. Roll nose bumper into channel

along entire lineup (up to 96’). We rec-

ommend that the nose bumper be left in

the store 24 hours before installing. DO

NOT STRETCH the bumper during

installation as it will shrink to its original

length and leave a gap.

Summary of Contents for Origin2 OSAA

Page 1: ...DELI C A S E S MODEL OSAA HANDBOOK INSTALLATION OPERATION 9 03 P061773M...

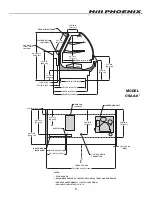

Page 2: ......

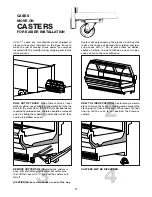

Page 4: ......

Page 29: ...25 NOTES...

Page 30: ...26 NOTES...