SERVICE 4

AQUATECH OPERATIONS, SERVICE AND PARTS MANUAL

A Product of Hi-Vac Corporation

SERVICE

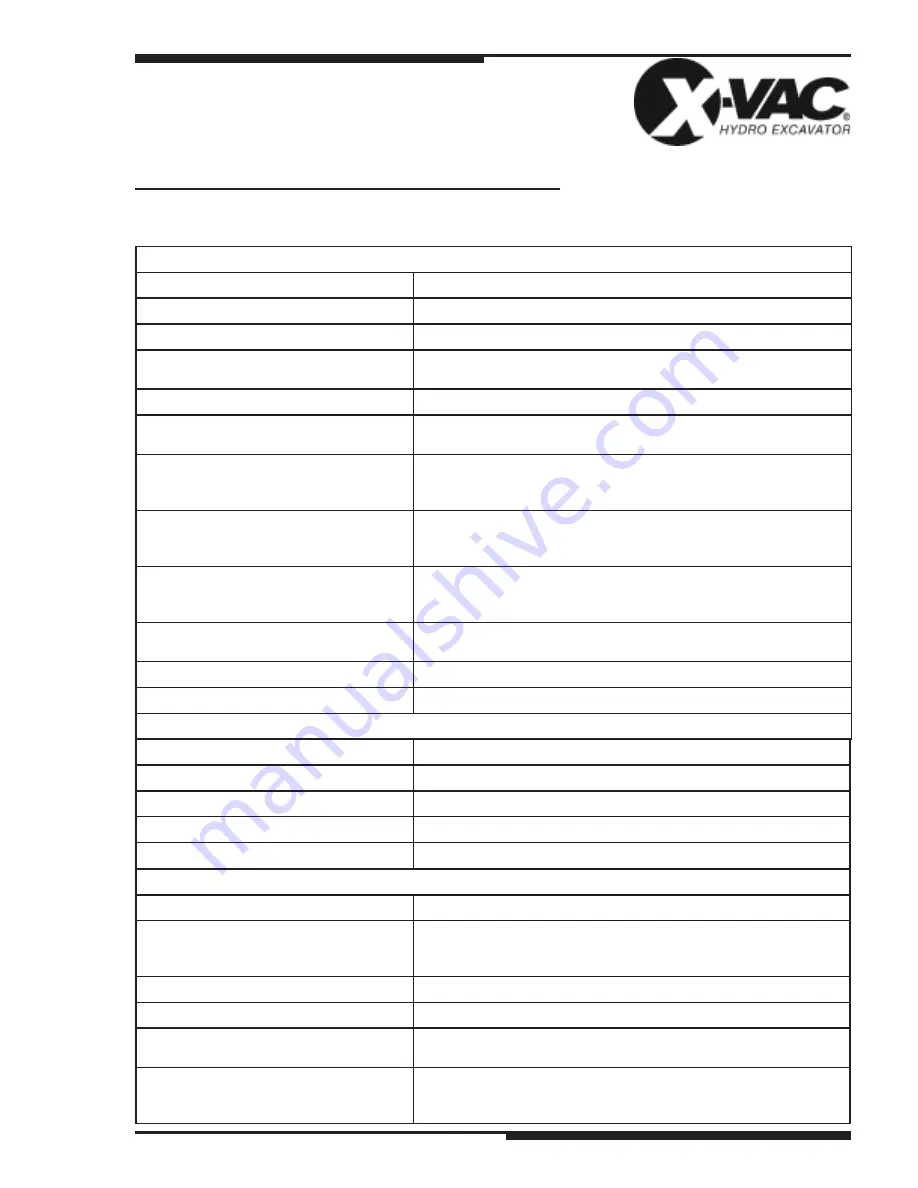

TROUBLESHOOTING COMMON PROBLEMS

The following is a list of possible problems which may be encountered during the life of this machine. Probable

causes are listed in this section together with recommended solutions to these problems. If the resolution of these

problems or any other problems are not readily apparent, contact your local authorized X-Vac dealer.

CONDITION: LOSS OF WATER PRESSURE

PROBABLE CAUSES

REMEDIES

Worn nozzle orifices.

Replace orifice or nozzle.

Wrong nozzle.

Change to correct nozzle.

Inadequate engine speed.

Adjust throttle cable and consult engine manual.

Check for correct gear.

Gate valve in suction line partly closed. Open valve.

Leaks in the high pressure water

system.

Locate and eliminate as required.

Water control valve leakage

bypassing or recirculating water back to

the water tank.

Clean, or replace seals.

Relief valve leaks or otherwise

malfunctions.

Replace. Note: Valves are set at the factory and adjustment

by inexperienced people could result in damage to equipment or

possible injury to personnel.

Pump starved for water.

Clean suction line and hose of obstructions, replace

suction hose if it leaks or is collapsed.

Clean suction line strainer. Open gate valve.

Transmission slipping.

Adjust, consult chassis manual, check automatic transmission

fluid level.

Gauge is inaccurate.

Replace gauge.

Worn valves or valve components.

Replace components as required.

CONDITION: WATER PRESSURE TOO HIGH

PROBABLE CAUSES

REMEDIES

Clogged nozzle.

Clean jets.

Incorrect nozzle.

Replace with correct nozzle.

Incorrect gear.

Shift to proper gear.

Overspeeding engine.

Reduce speed.

CONDITION: HAMMERING NOISE IN WATER PUMP

PROBABLE CAUSES

REMEDIES

Pump starved for water.

Clean suction line and hose obstructions, replace suction hose

if it leaks or is collapsed. Clean suction line strainer. Open

gate valve.

Valve stuck open with debris.

Disassemble and remove debris.

Worn valves or seals.

Inspect and replace as required.

Low oil level in water pump.

Check oil level and fill to proper level. If pump has been operat

-

ing with inadequate lubrication, inspect bearings.

Air in pump.

Bleed off air through blowout valves. Remove nozzle from

hose, pump water through until it flows at a smooth steady

stream.