Page 8

For technical questions, please call 1-888-866-5797.

Item 56844

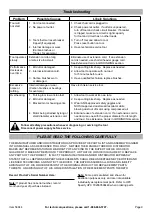

MAINTENANCE AND SERVICING

Procedures not specifically explained

in this manual must be performed

only by a qualified technician.

TO PREVENT SERIOUS INJURY FROM

ACCIDENTAL OPERATION:

Make sure that the Trigger is in the off-position

and unplug the tool from its electrical outlet before

performing any procedure in this section.

TO PREVENT SERIOUS INJURY FROM TOOL

FAILURE:

Do not use damaged equipment.

If abnormal noise or vibration occurs, have

the problem corrected before further use.

Cleaning, Maintenance,

and Lubrication

1.

BEFORE EACH USE,

inspect the general

condition of the tool. Check for:

• loose hardware

• misalignment or binding of moving parts

• cracked or broken parts

• damaged electrical wiring

• any other condition that may

affect its safe operation.

2.

AFTER USE,

wipe external surfaces

of the tool with clean cloth.

3. Store in temperatures no lower than 50-60°F.

NOTE:

The Rotary Hammer has airtight construction,

allowing long periods of use (approximately six

months of regular usage) before lubrication.