Page 10

For technical questions, please call 1-888-866-5797.

Item 56844

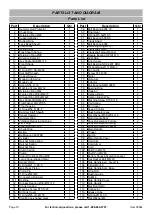

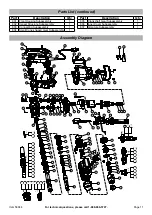

PARTS LIST AND DIAGRAM

Parts List

Part

Description

Qty

1

Hammer Rod Protector

1

2

Chuck Ring

1

3

Retaining Ring Ø26

1

4

Support Washer

1

5

Rubber Ring

1

6

Lock Bead Sheath

1

7

Insert Block

2

8

Spring Rack

1

9

Flex Sheath Spring

1

10

Retaining Ring Ø28

1

11

Direction Selector

1

12

Hex Socket Bolt M4

×

16

2

13

Front Shade

1

14

Cover

1

15

O Ring Ø13.94

×

Ø2.62

1

16

Dial Staff Sheath

1

17

Copper Sleeve

1

18

Mode Knob Spring

1

19

Mode Knob

1

20

Screw ST4.2

×

16

13

20A Machine Screw M4

×

12

1

21

Retaining Ring Ø42

1

22

Woolen Ring Ø30

×

Ø42

×

3

1

23

Oil Seal Ring Ø30xØ42x8

1

24

Hex Socket Bolt M6

×

25

4

25

Flat Washer Ø6

×

Ø10.5

4

26

Front housing

1

27

O Ring Ø54.5

×

Ø2.2

1

28

Hammer Staff Sheath

1

30

Impact Hammer

1

31

Hammer Ring

1

32

Vibration Reducing Cushion

1

33

Limit Ring

1

34

Steel Ball SØ7.938

8

35

Check Ring

1

36

Spring

1

37

Ball Bearing 6907RS

1

38

Cylinder

1

39

Ratchet Spring Ring

1

40

Ratchet Spring

1

41

Ratchet Ring

1

42

Clutch Spring

1

43

Clutch

1

44

Steel Wire Block Ring Ø32

1

45

Large Cone-shaped Gear

1

46

Impact Piston

1

47

O Ring Ø21.1

×

Ø3.5

2

48

Gas Press Piston

1

49

Piston Pin

1

50

O Ring Ø22

×

Ø2

1

51

Connecting Rod Asm

.

1

51.1 Bushing

1

52

Oiliness Bearing Ø32

×

Ø37

×

12

1

53

Crank Housing

1

54

Machine Screw ST5.5

×

25

6

55

Oil Tank Cover

1

56

O Ring Ø25.12

×

Ø1.78

1

57

Small Cone-shaped Gear

1

Part

Description

Qty

58

Ball Bearing 6904 VV

1

59

Final Gear

1

60

O Ring Ø5.5xØ1.05

1

61

Ball Bearing 608 RS

1

62

Crank Shaft

1

63

Ball Bearing 6004

1

64

Retaining Ring Ø20

×

1

1

65

Crankshaft Gear

1

66

Crankshaft Gear Washer

1

67

Needle Bearing HK101410

1

68

Seal Ring

1

69

Inner Cover

1

70

Ball Bearing NSK 6201 DDU

1

71

Oil Seal Ring Ø17

×

Ø32

×

7

1

72

Fan Guide

1

73

Screw ST4.8

×

58

2

75

Stator

1

76

Armature

1

77

Inductor

1

78

Ball Bearing NMB 608D

1

79

Bearing Ring

1

80

Housing

1

81

Carbon Brush

2

82

Carbon Brush Wire

2

83

Machine Screw ST3.5

×

16

4

84

Coil Spring

2

85

Fan Cover

1

86

Speed Control

1

87

Dual Indicator Lens

1

88

Flat Washer Ø5.5xØ14x1.6

2

89

Main Handle Seat

1

90

Shock Absorption Ferrule

2

91

Shock Absorption Spring

1

92

Shock Absorption Jacket

1

93

Main Handle

1

94

Trigger

1

95

Switch

1

96

Main Handle Cover

1

97

Cord Clip

1

98

Cord Armor

1

99

Cord

1

100 Split Pin Ø2

×

14

1

101 Shaft Pin Ø6

×

50

1

102 Bottom Shock Absorption Jacket

1

103 Hex Socket Bolt M6

×

20

2

104 Side Handle Asm. Steel Tie

1

106 T-Bolt M8

×

45

1

107 Side Handle Asm. Base

1

108 Wing Bolt

1

109 Depth Gauge

1

110 Nut M6

1

111 Side Handle Cover

1

112 Side Handle

1

113 Electrical Field

1

114 Connector

2

115 Grease Tube

1

116 O Ring Ø16

×

3.3

2

117 Flat Washer Ø4

1