LIMITED 90 DAYS WARRANTY

Harbor Freight Tools Co. makes every effort to assure that its products meet high quality and durability standards,

and warrants to the original purchaser that this product is free from defects in materials and workmanship for the

period of 90 days from the date of purchase. This warranty does not apply to damage due directly or indirectly,

to misuse, abuse, negligence or accidents, repairs or alterations outside our facilities, criminal activity, improper

installation, normal wear and tear, or to lack of maintenance. We shall in no event be liable for death, injuries

to persons or property, or for incidental, contingent, special or consequential damages arising from the use of

our product. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation of exclusion may not apply to you. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with transportation charges

prepaid. Proof of purchase date and an explanation of the complaint must accompany the merchandise.

If our inspection verifies the defect, we will either repair or replace the product at our election or we may

elect to refund the purchase price if we cannot readily and quickly provide you with a replacement. We will

return repaired products at our expense, but if we determine there is no defect, or that the defect resulted

from causes not within the scope of our warranty, then you must bear the cost of returning the product.

This warranty gives you specific legal rights and you may also have other rights which vary from state to state.

Visit our website at: http://www.harborfreight.com

Email our technical support at: [email protected]

For technical questions, please call 1-888-866-5797

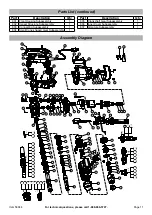

Copyright

©

2021 by Harbor Freight Tools

®

. All rights reserved. No portion of this manual or

any artwork contained herein may be reproduced in any shape or form without the express

written consent of Harbor Freight Tools. Diagrams within this manual may not be drawn

proportionally. Due to continuing improvements, actual product may differ slightly from the

product described herein. Tools required for assembly and service may not be included.

26541 Agoura Road • Calabasas, CA 91302 • 1-888-866-5797