Page 7

For technical questions, please call 1-888-866-5797.

Item 56844

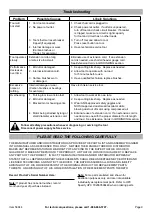

General Operation

TO PREVENT SERIOUS INJURY:

Wear ANSI-approved safety goggles, ear protection,

steel-toe boots, and dust mask during use.

Keep feet clear of Rotary Hammer.

Keep children and animals well

clear of the work area.

1. Check Bit for dullness, cracks, or other damage.

CAUTION!

Dull tipped bits can cause unnecessary

bit movement, resulting in tool wear and

possible injury. Use only sharp tipped bits.

2. Clearly mark the work area.

3.

Mode Knob

- Set the Mode Knob to the

required mode before using the tool.

NOTICE:

TO PREVENT DAMAGE, do not change the

Mode Knob while the tool is in operation. Make sure the

Mode Knob is entirely in the desired position before use.

a.

Hammer Mode

(top position)

The Bit will not rotate, but it will

impact forwards and backwards.

Do not use this mode

with spiral bits.

b.

Bit Rotation Mode

(middle position)

The Bit rotates. Use to adjust

Bit to optimal position before

switching back to Hammer

Mode or Hammer/Drill Mode

c.

Hammer/Drill Mode

(bottom position)

The Bit will simultaneously

rotate and impact.

4. Make sure that the Trigger is in

the off-position, then plug the tool in.

5. Set the bit against the work area.

CAUTION!

Keep power cord away

from moving machines.

6. Place one hand on the Front Handle and

the other hand around the Handle.

7. Press the upper part of the Trigger to start the tool.

Note:

Trigger will lock on. Press the lower

part of the Trigger to turn the tool off.

8. Push the tip forcibly down to begin striking material.

NOTICE:

Running tool with no load or

“empty blows” will damage the Rotary Hammer.

CAUTION!

Once activated, do not bear down,

or thrust forcibly against the work surface.

Note:

If the Rotary Hammer has not been used for

a long time or is being used in low temperatures,

the tool may require 3-5 minutes to warm up.

NOTE:

Carbon Brushes will wear during use.

The Carbon Brush Indicator will light if the

Brushes are worn.

If the Carbon Brush Indicator

lights, the worn Brushes will need to be replaced with

the included Brushes by a qualified technician.

Note:

During extended operation, periodically remove

the bit and re-lubricate the loading end with grease.

9. If a different speed setting is needed, press

the lower part of the Trigger, allow the tool

to stop, and adjust the Speed Knob.

10. When work is complete, press the lower

part of the Trigger to turn the tool off.

11. To prevent accidents, turn off the tool and

disconnect its power supply after use.

12. Clean, then store the tool indoors

out of children’s reach.