Some parts of the

TDF

loyal Henseleit customers will know from the TDR and the TDR-II. So the canopy is the same as it

is for TDR, as this design is still nice and aero dynamic - with good visibility - nothing to improve. A new decal design

changes the view, but also the old design can be used if wished. TDR-II design has to be modified a bit, but can than also

be used. TDR customers can also use there existing canopies - it fits without changes.

The approved main rotor of TDR II has been modified for 12mm main rotor shaft and 8 mm feathering spindle, to save

weight. The adjustable damping was implemented - so adjustments can be done on the field in seconds.

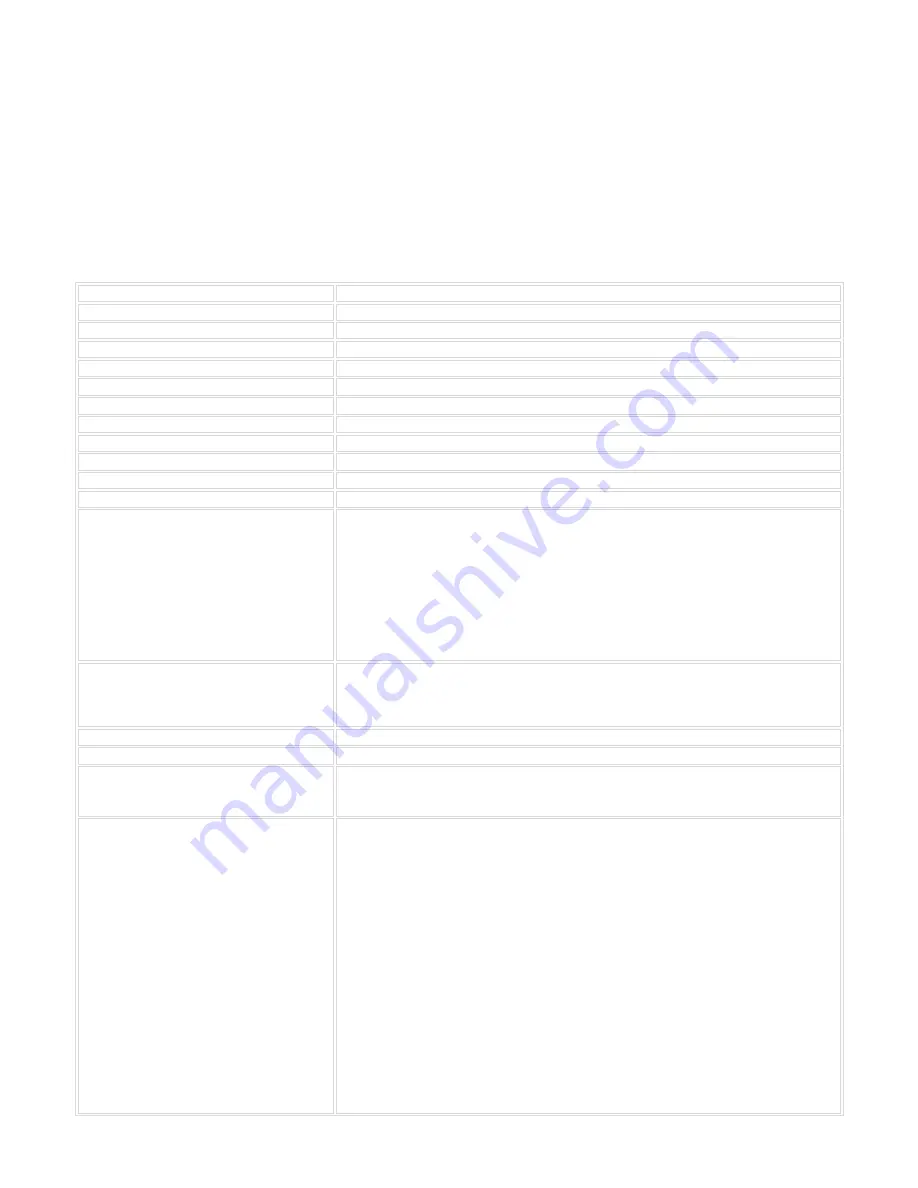

Technical Data:

Name

TDF

(

T

ree

D

ee

F

un)

Manufacturing and sales

Henseleit Helicopters

Main rotor diameter

up to 1600 mm

Rotor blades

680 - 720 mm

Recommended rotor blades

710 mm / 175 - 210 g

Tail rotor blades

up to 110 mm carbon blades

Empty weight of the mechanic

approx 1800 g

Total weight - depending on used components 3.6 - 4.8 kg

Total length - tip of canopy to end of tail

1390 mm

Total height

390 mm

Maximum width of skits

190 mm

Maximum width of canopy

140 mm

Recommended motor

PYRO 650

– 78 (6S setup)

PYRO 650

– 65 (7S / 8S setup)

PYRO 700

– 52 (for 10S)

PYRO 700

– 45 (for 12S)

Maximum motor PYRO 750

– 45 Competition (for 12S)

Recommended ESC

JIVE PRO 120+ HV

KOSMIK 160+HV depending on motor and flight syle (recommended only for PYRO 750

motors)

Gear ratio main rotor to tail rotor

1 : 5,56 (tail rotor is running during auto rotation)

Gear ratio motor to main rotor

9,27 : 1

Maximum flight pack size (L x W x H)

340 mm x 60 mm x 62 mm

When using 6S or 7S, the flight pack should be a weight of minimum 800 g.

Recomended servos and some general things

In gereral al standard servos can be used, but the

TDF

can also be flown with mid size servos

due to his weight and Linear Drive System, as 80 Ncm torque is more than enough.

Normally these servos are only half in weight of standard ones - so a total saving of about 160

g is possible.

Important is, tha there is no play in the servo and that the are precise in finding and holding

their position.

The enormous torque of up to 300 Ncm, the manufacturers are beating each other, I believe in

substantial exaggerating. Servos with more than 150 Ncm using in this helicopters are not

useful.

Even with 3 midi size servos the swash plate is pushed with nearly 25 kg (2 ½ baskets of

water).

Considered that the rotor blade with cyclical input and 1800 RPM on the main rotor change

from one side to the other about 30 times a second - you can imagine that the forces cannot

be as high, as the stud bolts would not stay in the plastic ball link if the force would be as high.