13

T51002 E

InstallatIon, servIce and troubleshootIng Procedures

INSTAllATION

Installation of TIREMAAX

®

PRO and CP systems can

be done on new or existing axles. For application

and installation questions, refer to CONTACT

INSTAllATION MATERIAlS AND SUPPlIES

In addition to the hardware provided, the installer shall

provide the following:

• Controller assembly

mounting bolts

•

PPV

, Pressure Protection Valve.

•

Indicator lamp and wire

, if not configured as part

of TIREMAAX kit (Figure 41 to Figure 42).

•

Spindle plug driver and handle

3

page 19), unless the spindle plugs are already

installed in the axle from the factory.

•

Air lines and fittings

as defined in Figure 34 to

INSTAllATION INTRODUCTION

Installation procedures are divided into sections

relative to installation requirements of both suspension

and trailer. Refer to Table 3, below, to determine the

best starting point for your application.

If

START AT

New system

with nothing

installed

Axles are pre-drilled

but no

TIREMAAX hardware has been

installed

Axle Component Installation

on page 16

Axle hose and spindle plugs

are already

installed

, but

undressed

HUBCAP INSTALLATION on

page 21

System hardware is already

installed on a

dressed axle

TIRE HOSE INSTALLATION on

page 23

Table 3:

Installation starting points

3

Components unique to TIREMAAX

®

are available only from

Hendrickson.

AXlE PREPARATION

The first stage of TIREMAAX installation is axle

preparation. Starting with Figure 5, this section defines

procedures for drilling holes and other steps required

to prep a Hendrickson axle to receive hoses and

fittings.

NOTE:

The TIREMAAX system is compatible

with most spindle nut systems. To avoid

interference when using a castle (cotter pin-

locked) spindle nut system, the use of an

extended hubcap is required. The cotter pin

cannot be longer than one inch.

WARNING: Chock all wheels before beginning

this installation procedure. Never

work under a vehicle supported

ONly by a jack. Refer to PREPARING

for details.

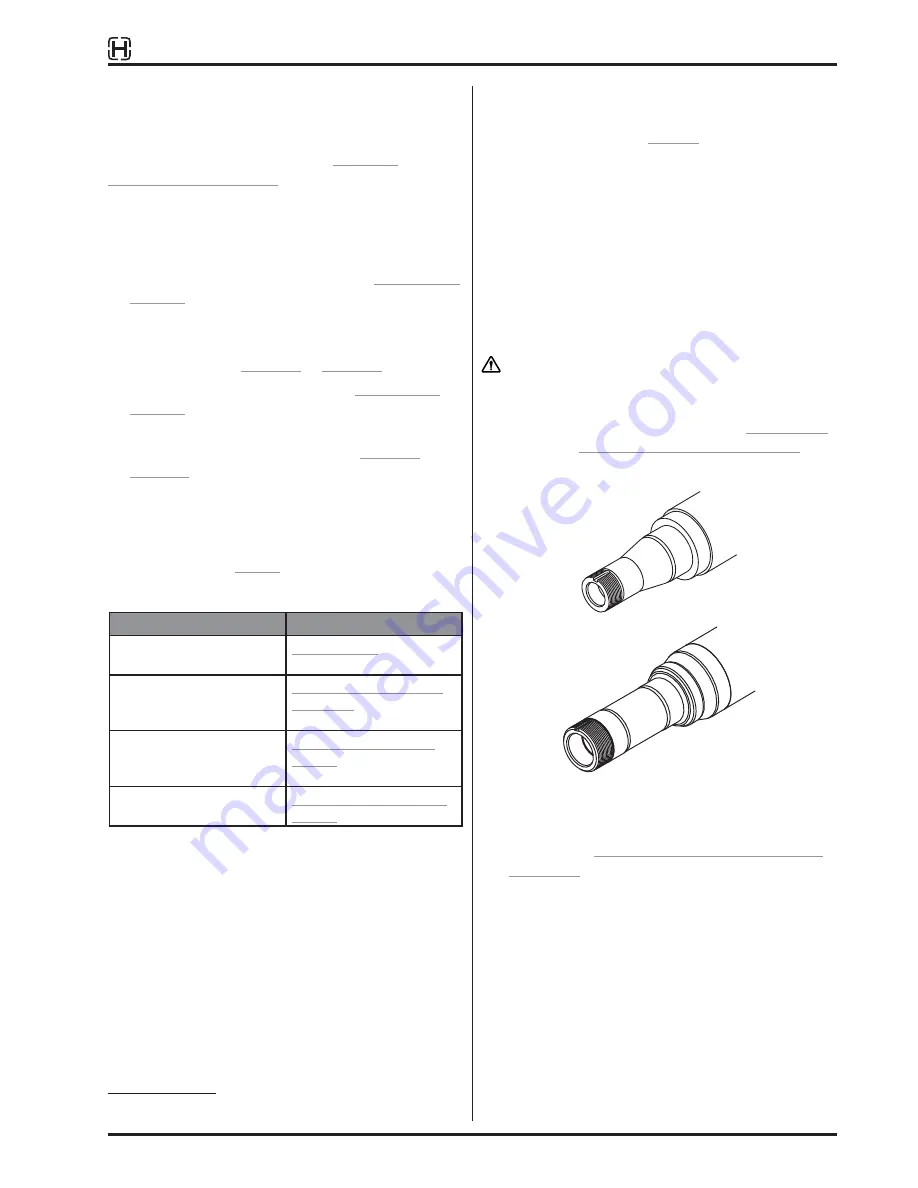

HN spindle

HP spindle

Figure 5:

Axle spindle identification

1.

Chock

wheels to keep trailer from moving

according to PREPARING TRAILER FOR SERVICE

2. If the wheel end is oil lubricated, drain oil from the

hubcap and discard oil.

3.

Remove

hubcap bolts and hubcap.

4.

Remove

spindle plug from the spindle.

5.

Remove

in-axle filter.

6.

Inspect

spindle plug bore and remove any burrs

or sealant.