4

1.0 INTRODUCTION

1.1 Equipment identifi cation

The unit’s identifi cation number (specifi cation or part number) model, and serial number

usually appear on a nameplate attached to the rear panel. Equipment which does

not have a control panel such as gun and cable assemblies is identifi ed only by the

specifi cation or part number printed on the shipping container. Record these numbers

for future reference.

1.2 Receipt of equipment

When you receive the equipment, compare it with the invoice to make sure it is

complete and inspect the equipment for possible damage due to shipping. All

machines dispatched have been scrupulously checked. However, should your

machine not work properly, consult the section on TROUBLE SHOOTING in this

manual. If the fault persists, consult your authorized dealer.

2.0 SAFETY WARNING

2.1 General instructions

This manual contains all the necessary instructions for:

- the installation of the equipment;

- a correct operating procedure;

- an adequate maintenance of the equipment.

Therefore, be sure this manual is carefully read and understood by the maintenance

and technical operators.

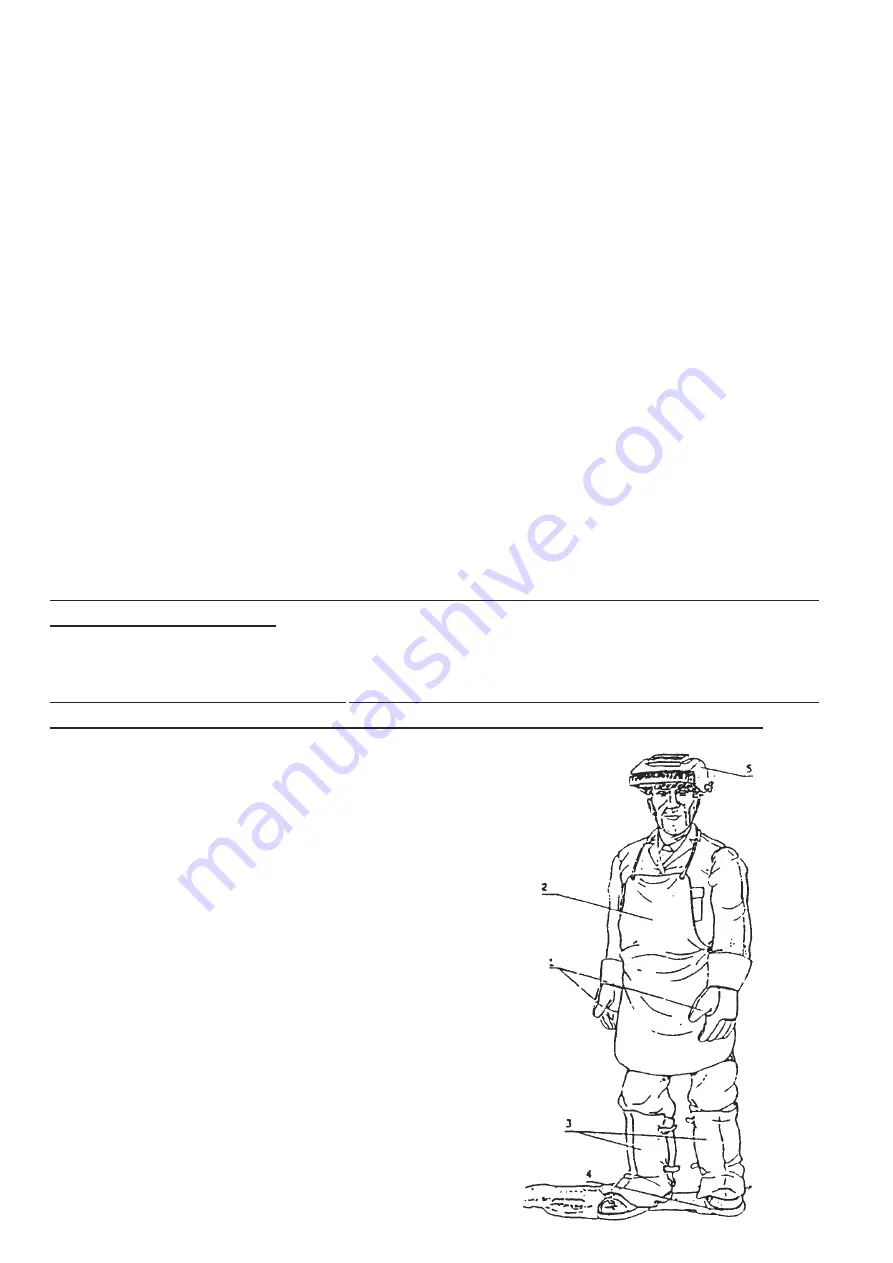

2.2 Location

Welding processes of any kind can be dangerous not only to the operator but to any person

situated near the equipment if safety and operating rules are not strictly observed.

Therefore the owner and the operator must

be aware of all possible risks so that they may

take the necessary safety precautions to avoid

any kind of accident at work.

The main precautions to be observed are:

-Operators should protect their body by

wearing non fl ammable, close fi tting protective

clothing, without pockets or turned-up trousers.

Oil or grease should be carefully removed from

all articles, before wearing. Operators should

also wear closed safety boots with steel toe

caps and with rubber soles ( Fig. 1).

1. Leather gloves

2. Leather aprons

3. Shoes cover

4. Security shoes

5. Face masks